Screwdriver attachments greatly facilitate repair and construction work, since the process of assembling and dismantling various structures is simplified through the use of this convenient and useful tool. Removable devices allow you to expand the scope of its application, in this article you can familiarize yourself with the features of the most demanded of them. The text contains brief overviews of accessories designed for working with wood, metal and drywall.

Content

- 1 Screwdriver bits: general information, basic tip types

- 2 What are the names of screwdriver attachments and what features they have

- 3 The main types of nozzles for a screwdriver

- 4 The main types of polishing and grinding attachments for the screwdriver

- 4.1 Varieties of attachments for a screwdriver for grinding

- 4.2 Features of polishing tips for screwdriver

- 4.3 The main types of attachments for a screwdriver for cutting metal and wood

- 4.4 Overview of screwdriver bits for cutting sheet metal and plastic

- 4.5 Scope of application and features of the saw attachment for the screwdriver

- 4.6 Characteristics of attachments for drywall screwdriver

- 4.7 Varieties of screwdriver attachments for self-tapping screws in tape

- 5 How to use a strap screwdriver

Screwdriver bits: general information, basic tip types

Like removable attachments for drills, screwdriver bits belong to the category of devices that are aimed at expanding functionality. Thanks to them, this tool can be turned into a universal screwdriver or a compact machine for cutting sheet metal. The range of handpieces offered by manufacturers is very wide. With their help, you can carry out construction work of any complexity at home, which provided such a popularity to the screwdriver.

Some buyers don't see the difference between a drill and a screwdriver, but there is one. Moreover, these differences must be taken into account when choosing removable nozzles for performing certain jobs. Firstly, the rotational speed of a screwdriver is much lower than that of a drill. Secondly, it lacks a moment of inertia. In other words, if you press the shutdown button, the screwdriver will instantly stop, unlike the drill, which will rotate for some time.

All screwdrivers have a release clutch. It is designed to adjust the tightening force. Some models do not have a cartridge. Instead, a hex socket is installed in which the bits are fixed.

There are several types of tools, each of which can provide specific benefits:

- Small screwdrivers - used as a miniature electric screwdriver for repairing watches, telephones and small appliances.

- Folding screwdrivers - these models are designed to work in a confined space that a regular tool cannot reach. If the handle interferes with work, you can simply remove it.

- Drill Drivers - designs that are hybrids. They combine the best properties of each instrument.

Important! When working with a screwdriver, it is advisable to use protective equipment. This is especially true for operations such as grinding and polishing, during which debris and dust are generated.

What are the names of screwdriver bits and what features they have

Detachable bits that are installed on a screwdriver are called bits. These devices are inserted into the chuck. Bits are cross-shaped, square, straight-slotted, hexagonal, star-shaped, etc. The buyer can purchase an accessory for any type of screws.

In order for the fastener to hold tightly to the bit, you need to choose the right size and shape. The bit must match exactly with the notches on the screw. Otherwise, you may not only damage the bits and break the tool, but also get injured. Using a special holder completely solves this problem. With its help, you can install any type of bit on the screwdriver, regardless of its length and size.

There are several types of holders:

- Magnetic - equipped with a built-in magnet. It attracts the bit along with the screw, so there is no chance that the bit and fasteners will be poorly fixed.

- For long self-tapping screws - it looks like a tube that fixes the self-tapping screw in the process of twisting, preventing it from loosening.

- For hex bits.

These are far from all the existing types of holders, the list contains only the main ones and the most popular ones.

The main types of nozzles for a screwdriver

On sale you can find a lot of devices that expand the functionality of the power tool. The user can get, thanks to the attachments for the screwdriver, pump, mixer, saw, polishing brush and other types of specialized equipment.

All removable devices are divided into three main groups:

- Combined nozzles.

- Tips for special purposes.

- Basic nozzles.

The working element of the handpieces belonging to the main group has the form of a cruciform or hexagonal head. Such attachments for a screwdriver are suitable for self-tapping screws of any type. They provide excellent adhesion to the fastener. In some nozzles, the heads are magnetized, which greatly facilitates the screwing process. In terms of technical characteristics and capabilities, such tips are similar to screwdrivers.

Existing species bit for screwdriver differ in the shape of their working part

Combined attachments belong to the category of universal attachments. Unlike the main tips, they have a working body on both sides. Each end of the combination bit has its own size and attachment system. For convenience in the process of work, the unnecessary part of the tip is simply dismantled.

Bits for special purposes are mainly presented in the form of attachments for a screwdriver for twisting wires. With their help, you can also control the depth of unscrewing and screwing in fasteners located at an acute angle.

Useful advice! To decrease or increase the rotational speed of the nozzle, it is enough to weaken or, conversely, increase the pressure on the start button.

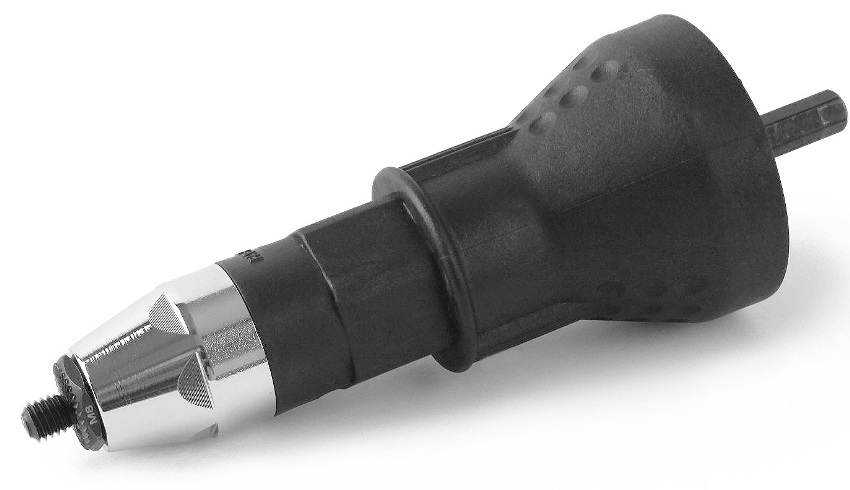

Characteristics of rivet bits for screwdriver

Traditional one-piece rivets are rarely used. Many professionals prefer to use a welding machine. However, not every master has such equipment in his arsenal, and also has the skills necessary to work with it. In this case, the best option would be a rivet attachment, which is installed on a screwdriver.

Such attachments can be used on electric and cordless tools for mounting nut rivets and other core fasteners.

It should be noted that screwdriver attachments for rivets can only be used on those tool models where there is a reversible drive. These fixtures are designed for mounting aluminum or steel fasteners, the diameter of which is in the range of 2.4-5 mm. They can also be used to install sleeves made of non-ferrous metals, the diameter of which does not exceed 25 mm.

If a battery-powered screwdriver is used to install the rivets, you need to make sure that the battery voltage does not exceed 12 V. The installation process itself is not particularly complicated, and the attachments are compact enough to be stored together with the screwdriver in one case.

The main types of angle adapters for a screwdriver

Angle adapters allow you to unscrew and tighten fasteners in hard-to-reach places. Such attachments greatly simplify the work, because the tool can be held perpendicular to the surface, and the screws can be screwed at an angle, both left and right.

Taking into account the technical characteristics, as well as the functional purpose, there are two types of angle nozzles for a screwdriver:

- flexible;

- tough.

Flexible design attachments use flexible coupling to change the direction of the torsion axis. Outwardly, the device looks like a drill used in dental clinics for dental treatment. The removable tip consists of a flexible shaft that connects the work bit to the screwdriver chuck. This type of attachment makes it easier and faster to work in hard-to-reach places where you need to unscrew the screws.

Note! Flexible angle bits for the screwdriver are not suitable for fasteners that are made of strong alloys.

Rigid adapters are short attachments that mechanically change the direction of the pivot. Unlike the previous version, the cartridge of this device is much stronger. Rigid adapters allow mounting and dismounting of fasteners from either side. Such attachments are usually used in professional screwdrivers, whose motor is designed for high loads and strong vibrations.

The main types of polishing and grinding attachments for the screwdriver

The polishing and grinding attachments for the screwdriver are a large group of removable accessories, including many varieties. In this category, you can find handpieces for different tasks:

- polishing metal, wood and glass surfaces, as well as varnished products;

- cleaning products made of metal from corrosion and remnants of old paintwork;

- grinding wood and metal surfaces.

Thanks to the huge variety of screwdriver attachments for grinding, you can choose the tips for operations that cannot be done with standard methods.

Varieties of attachments for a screwdriver for grinding

There are more than ten varieties of screwdriver tips with which you can grind surfaces. Removable devices of this type consist of a rod on which an abrasive material is fixed:

- sandpaper;

- hard abrasive;

- stiff fabric such as felt

- brushes.

The most popular among the craftsmen are the following types of removable tips:

- Plate - these products can be rubber or plastic. Equipped with fixed and adjustable pins.

- End - made of hard and soft materials, can have various shapes (drum, washer, cone).

- Cup - brush attachments for a screwdriver with brass or metal fibers, as well as tips with soft foam or felt filling.

- Disc - removable devices with soft padding or bristles made of brass or steel wire.

- Drum - an emery belt is used as an abrasive, suitable for processing holes and end zones of glass products.

- Serrated - consist of several elements covered with sandpaper. They are used for processing surfaces with complex geometry.

Note! If you wish, you can use a compact screwdriver with an end bit for processing jewelry. The nib is so precise that it allows you to sand fine details on precious metal jewelry.

Features of polishing tips for screwdriver

After processing the product with a polishing attachment, its surface becomes perfectly smooth. For this, an end disc is used to remove the microscopic top layer of material. Thanks to this, the thickness of the product does not change.

Related article:

Drill bits for various purposes for work in the home workshop

The main types of accessories for cutting, grinding, polishing and other tasks. Accessories for working with metal, plastic, wood.

The screwdriver attachments for polishing various surfaces have a stop wheel with fasteners for fixing the polishing material. This element is held by a threaded tip. Since the tool shaft can rotate both to the left and to the right, you can find accessories on the market with the appropriate type of connections.

During operation, the polishing disc on the attachment wears out, so it should be periodically replaced with a new one. Replaceable products are thin (only a few millimeters). They are usually made from polyurethane. Although there are other options - from felt or wool of natural or artificial origin.

Some tip types can be used for polishing automotive bodywork and glass, as well as products made from polycarbonate. During operation, such attachments must be kept parallel to the surface to be treated.

The main types of attachments for a screwdriver for cutting metal and wood

To perform many construction and repair work, a jigsaw is required, attachments for a screwdriver in the form of special scissors or a reciprocating saw can become an almost complete replacement for this tool.

There are several types of removable scissor tips for cutting metal:

- disk;

- turbo;

- nibbling;

- sector.

Each of them has its own principle of work and is designed for cutting sheets of a certain thickness.

Overview of screwdriver bits for cutting sheet metal and plastic

The disc shears are equipped with two steel discs. One of them rotates due to the rotational motion transmitted from the chuck to the tool. The design of the cutting disc for a screwdriver is designed in such a way that the metal is cut in a straight line even without marking.

Circular shears are used in cladding and roofing works using:

- metal tiles;

- galvanized;

- siding;

- metal profile.

Note! Circular shears are maneuverable enough to create curly sections, but they cannot cope with the manufacture of complex metal parts.

The nibbler for metal screwdriver is an attachment that has high maneuverability and allows you to get a very accurate cut. The edge turns out to be as smooth and accurate as possible, so the possibility of cutting your hands when working with metal is almost completely excluded.

Turbo scissors - a screwdriver attachment that works on the same principle as conventional scissors, but cutting is much faster. This device is suitable for cutting sheet metal, plastics and other materials with a high degree of rigidity. The advantage of this nozzle is that there is no vibration during operation. This ensures that the back of the claw does not damage the surface it touches.

This concludes the list of attachments for a metal cutting screwdriver. Sector-type scissors are used in the installation of communication systems. They are suitable for cutting plastic pipes as well as power cables.

Scope of application and features of the saw attachment for the screwdriver

Even with a jigsaw in the house, some types of work simply cannot be done with this tool. In such cases, the capabilities of the reciprocating saw will be useful. This type of screwdriver bit is usually used for cutting wood, although it can be used to cut thin plastic and sheet metal. Reciprocating saw can also be used for garden maintenance at a summer cottage. This type of attachment is suitable for pruning young trees.

Usually, the set comes with three interchangeable blades of different lengths - 10, 15 and 23 cm (this is only an approximate value, which may vary depending on the manufacturer). The purchase of such a tip will cost several times less than the purchase of an electric saw. The nozzle is capable of operating at a speed of about 2000 rpm.

The body of the removable device is made of very durable plastic. The blades are made of the same material. Despite this, they are able to cope with cutting solid wood.

Note! When cutting the material, you need to firmly press the bracket against it, which will serve as a stop. This will reduce vibration and maintain the effectiveness of the reciprocating saw.

Characteristics of attachments for drywall screwdriver

Plasterboard is widely used in repair work as a rough finish, as well as for the construction of decorative structures and partitions. The sheets are fixed to the ceiling and walls with self-tapping screws. For their installation, a conventional screwdriver is used, which allows you to control the installation of each fastener. This method is quite laborious and time-consuming. To speed up and simplify it, you can use a special drywall nozzle and a tape screwdriver.

For drywall, bits with PZ and PH markings are used, which have different slot shapes. In PZ nozzles, the faces are parallel to each other.Thanks to this, the screw head is rigidly fixed and centered.

In attachments with PH marking, the slots diverge slightly. This is so that the tool can self-align the center even when it is at an angle. If the pressure is excessive, the edges of the nozzle will simply pop out of the fastener head without damaging it.

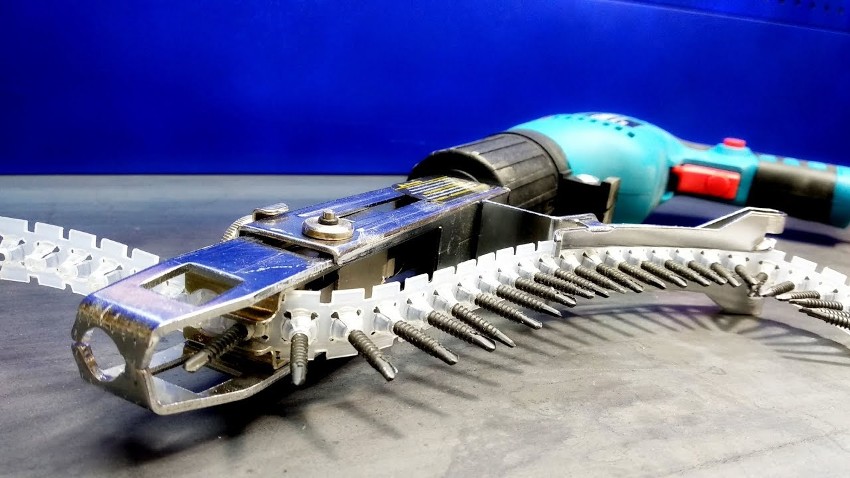

Varieties of screwdriver attachments for self-tapping screws in tape

To fix the screws with a screwdriver, not only bits, but also tapes can be used. They are part of the automatic fastener feed devices. Such attachments can speed up installation work by about 2-3 times. The advantage of using them is that the master does not need to take a new self-tapping screw every time and install it on the bit.

Manufacturers produce two types of drives with a tape feed mechanism for self-tapping screws:

- Removable tape attachments for the screwdriver - if necessary, such a tip can be removed and additionally screwed on the self-tapping screw. This option is in high demand among consumers, although it is not without its drawbacks. The fact is that the attachment must be purchased together with a screwdriver.

- Stationary mechanisms - in this case, the attachment together with the screwdriver is a one-piece structure. Such a tool belongs to the category of narrowly targeted and can only be used with tapes.

Tape screwdrivers are battery and mains. Devices that plug into an outlet are half the price. However, they are completely dependent on the mains power and are not so convenient to use, since the hanging cord creates certain inconveniences. This is especially true when installation work is carried out on the ceiling.

Useful advice! To increase the efficiency of polishing, the disc of the attachment must be lubricated with a special polishing paste.

There are two types of drives with a tape feed mechanism for self-tapping screws: stationary and removable type

How to use a screwdriver with ribbon nozzle

The tape nozzle cannot be called universal, since it is used exclusively for tightening self-tapping screws during the installation of drywall sheets. Many manufacturers have taken care of the user experience by equipping some screwdriver models the ability to work without a tape. Such a tool allows you to tighten single screws. To do this, you need to remove the tape, and then replace it with an adapter and a bit of the appropriate size. The process of installing the ribbon nozzle is somewhat more complicated.

How do I change the bit on a tape-type screwdriver? To do this, follow these steps:

- The tool kit includes an extended bit. It must be inserted into the detachable bit before it is installed on the screwdriver.

- The nozzle is fixed in the chuck of the screwdriver.

- Next, you need to install the "store" on the tool. This must be done so that not a self-tapping screw is located near the muzzle, but the protrusion of the tape. Fasteners are fed in automatic mode, which is activated after pressing the start button.

This completes the preparation of the tool for work. During operation, the screwdriver is pressed against the drywall. This is done so that the sheet is grabbed and securely connected to the profile. Before starting work, it is advisable to apply markings on the drywall. In appropriate places on the material, using a pencil or marker, you need to put points.

It is necessary to move the screwdriver with a tape nozzle in the right direction, pressing it against the surface of the drywall

Assembly work using a tape screwdriver is fast and efficient. All self-tapping screws are recessed to the same depth, so the result is neat and of high quality.

It is desirable that the screwdriver has a function of fixing the start button. In this case, the tool will run continuously. The master will only need to move the screwdriver in accordance with the markings in the desired direction, pressing it against the surface of the drywall. When the fastener is screwed on, the assembly snaps off, the tape with other screws moves.

The list of nozzles that increase the functionality of the screwdriver does not end there. This article covers only the main ones. To purchase a high-quality handpiece for a power tool, you need to pay attention to such nuances as the material of manufacture (molybdenum, tungsten, vanadium, chromium), the presence of a protective coating on the bit (titanium, nickel or diamond sputtering) and the reliability of the manufacturer. According to consumer reviews, the following companies are recognized as the best brands: Torx, Slot and Pozidriv.

While in a specialized store, you definitely need to make sure that the seller has certificates confirming the quality of the products, because the service life of the nozzles depends on this. In addition, the buyer must be provided with a guarantee.