From this article, you can find out what snow holders on the roof are: the purpose and existing types of products, their characteristics and rules of use. The text contains a detailed description of corner, tubular, lattice, as well as point snow catchers and the basic rules for their installation on metal, soft, folded and other types of roofing.

Content

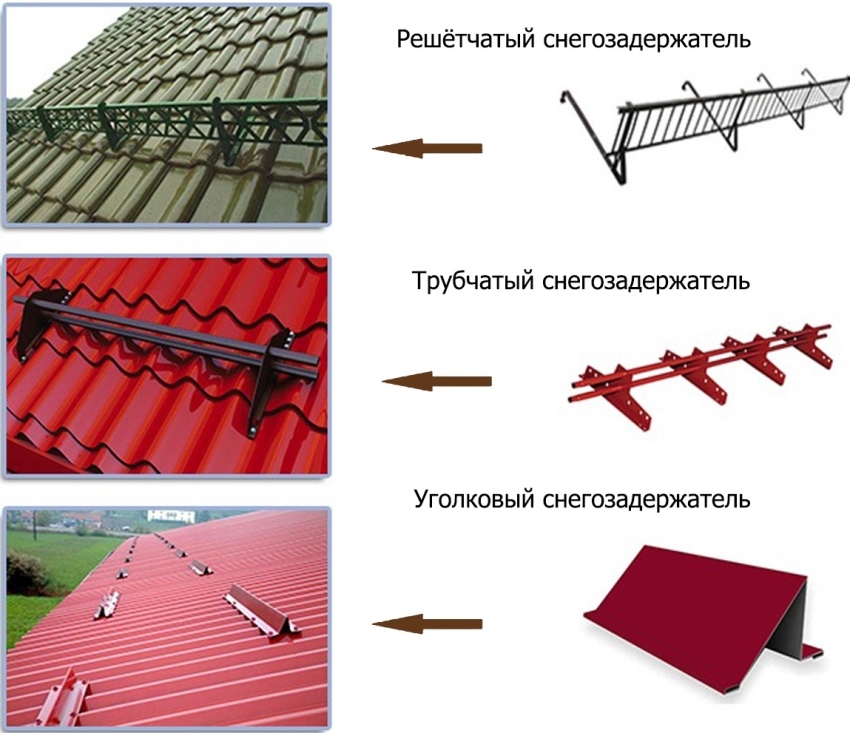

The main types of metal profiles for keeping snow on the roof

Avalanche snow from the roof is a common problem in regions where winters are accompanied by a large amount of precipitation. To solve it, special devices are used - snow holders. These structures keep rainfall on the roof, which, as it thaws, gradually flows down the drains.

There are several types of snow guards. These products are selected taking into account several factors:

- type of roof;

- roof angle;

- the thickness of the snow cover typical for the region.

Consumers can buy roof snow guards along with the roofing material when the house is still under construction, or they can be purchased as additional equipment for a finished building. These devices may have different names depending on the functions they perform.

Snow-blocking rails ensure complete containment of rainfall on the roof. They are also called snow barriers. In this case, even partial melting of snow layers is impossible. The accumulated precipitation will melt and leave the roof in a natural way.

Snow cutters serve a different function. They are designed to cut the snow layer into several small pieces. Thanks to this, the energy of the avalanche falling will be minimal and safe.

Snow holders differ not only in the material of manufacture, but also in shape, size, and degree of reliability.

Consumers can buy snow protectors of the following types:

- Lattice.

- Corner.

- Tubular.

- Point.

In addition, you can make your own roof protective structures. For this, wood is most often used.

Useful advice! When choosing snow catchers, it is imperative to pay attention to how much snow the structure is designed to hold. Otherwise, it will not be able to fully fulfill its function and ensure safety.

Universal tubular snow holders 3 m: price and design features

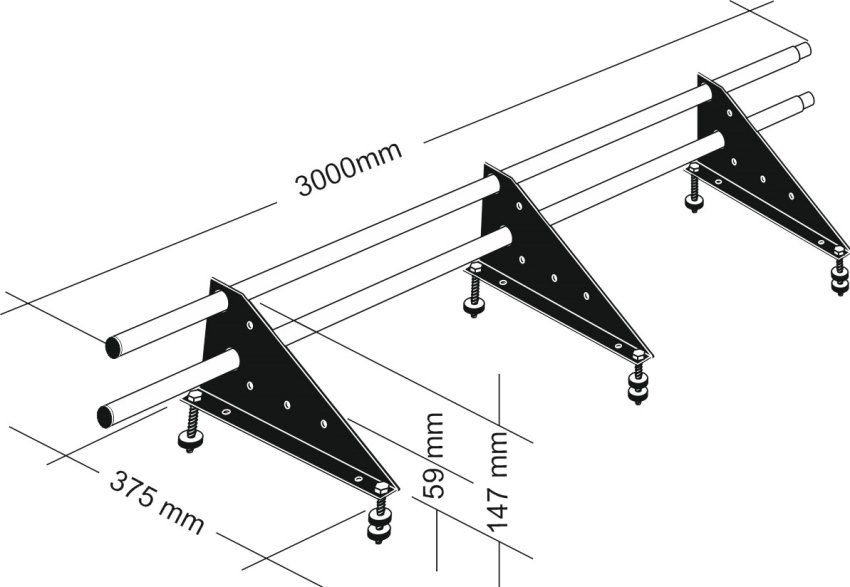

Tubular products are made from brackets and a pair of pipes, the diameter of which is 1.5-3 cm. The height of such a structure is 15 cm. The bracket looks like a vertical plate in which holes are made for installing pipes. There is a shelf in its lower part. It is used to fix the snow guard on the roof. Screws for metal with a hexagon head (0.8x6 cm) are used as fasteners.

The appearance of the bracket may vary. It depends on the type of roofing where it will be installed. It is desirable that there is a distance of about 2-3 cm between the roof surface and the first pipe, and 8-10 cm between the pipes.

Tubular structures cut the snow layer into several pieces. They are reliable and can handle a lot of pressure. This category of products can be considered universal, since tubular snow cutters are suitable for almost any type of roof:

- sheet;

- soft;

- tiled.

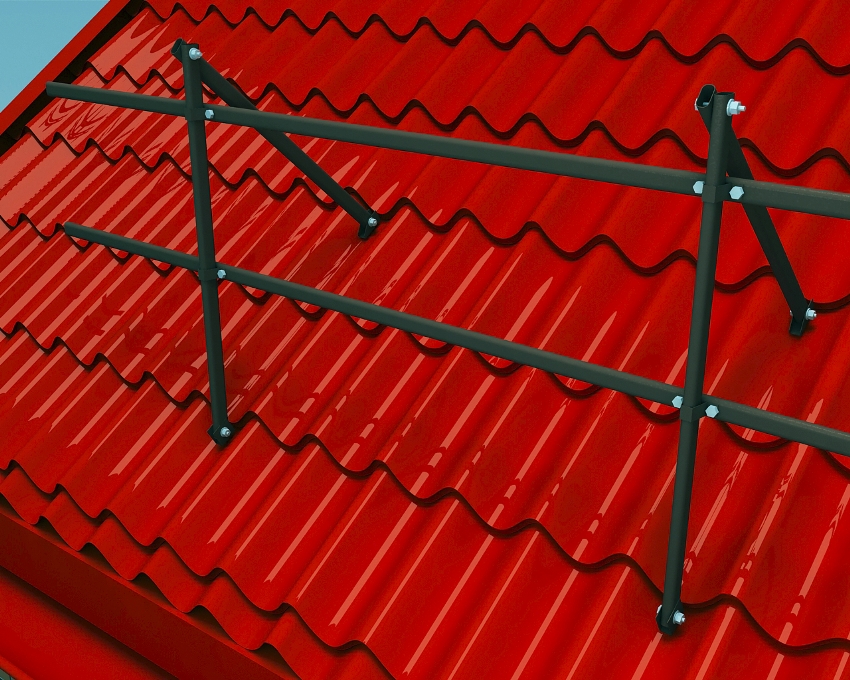

Installation of tubular snow guards is carried out along the slope along the entire perimeter of the building

Installation of structures is carried out along the slope along the entire perimeter of the building. In this case, the products are not arranged randomly, but in a row. If the snow load in winter is high, you can install two rows of protective structures at a distance of 2-3 m from each other. Moreover, the lower one is fixed with an indent of 0.4-0.5 m from the eaves overhang. The shade of the snow holders can be matched to the tone of the roof, therefore, after installation, these structures are not striking.

For the manufacture of tubular snow retainers, galvanized steel is most often used. From above it is covered with paint, which is matched to the color of the roof. Thanks to this, the product not only fits into the general appearance of the building, but also turns out to be durable. What's more, the paint provides corrosion protection.

Average prices for tubular snow guards:

| Brand name | Collection | Price, rub / piece |

| Borge | Economy | 980 |

| Grand Line | Universal | 1350 |

| Grand Line | GL-O RAL | 1765 |

Note! Tubular railings are suitable for roofs with a steep slope (up to 60 °), where there is often snow movement due to high pressure. If the slope of the roof exceeds this indicator, there is no need to install snow holders, since precipitation on the surface does not linger, but immediately crumbles.

Features of lattice roof snow holders: price and characteristics

Lattice snow holders in a universal design have the form of brackets on which the lattice is fixed in a vertical position. All parts of the product are made of galvanized steel, opened with a paint composition, which allows you to choose a structure for any roof color.

Lattice snow holders are made of galvanized steel and coated with a protective paint composition, which allows you to choose the structure to match the roof

The size of the grates can vary. The largest options have a height of about 15-20 cm. The size of small gratings does not exceed 5-7 cm. The level of strength depends on the size of this part, and the ability of the structure to hold a certain amount of snow.Large steel grates can withstand the weight and pressure of large amounts of ice precipitation. As a rule, snow retention on the roof is provided at all times. Precipitation leaves it only in the form of melt water.

Lattice type products are mounted on long roof slopes with a steep slope. The presence of such a design ensures that blocks of snow do not fall on the head of passers-by. The efficiency of the grate depends on its height. There are no restrictions on the material of the roof, since all types of fasteners are provided for this type of protective structures.

On sale you can find snow guards where the grille is welded to the longitudinal pipes. This configuration improves product reliability. Installation of lattice structures is carried out on a slope along the eaves. If the snow loads in the region are large enough, other types of protective fences, for example, lamellar snow pads, can be installed as an addition. The same applies when the slope length exceeds 5.5 m.

The average price of lattice structures for natural tiles (ceramic or cement-sand) is 4250 rubles / piece. The purchase of products intended for seam roofing will cost about 3200 rubles / piece.

Note! Under the pressure of large amounts of snow, the gratings can bend. In this aspect, tubular structures are more reliable. The strength of lattice snow guards depends on the shape of the guides or brackets, as well as their quality. You should not buy products where these parts are the same thickness as the grille.

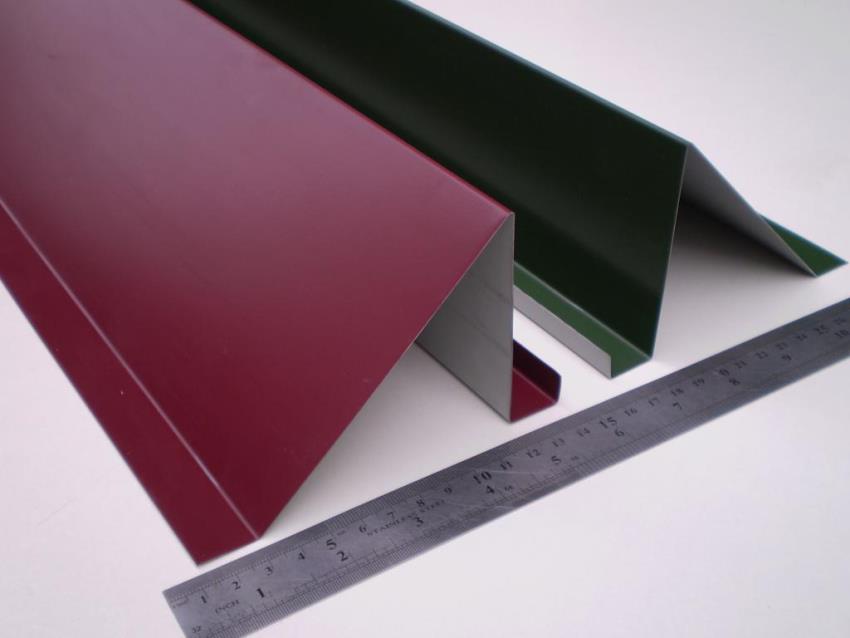

Lamellar or corner snow holders for metal tiles

If a small amount of precipitation accumulates on the roof, you can limit yourself to buying corner snow holders. Most often they are used on roofs made of corrugated board or metal tiles, since these products are made from the same material and in the same color.

Angular metal structures have a bent triangular shape with two edges, equipped with shelves for fasteners. The height of this type of snow guards is 4-6 cm. Corner fences are designed for roofs with a slight slope (no more than 30º), since the structures are not able to withstand high pressure.

Products are attached directly to the roofing material, and the upper wave of the coating is no exception, where the fences are also fixed. Installation of snow guards on a metal roof is carried out along the ridge. This is done in a checkerboard pattern. Products are mixed in several rows (at least 2) with a step of 0.5-1 m.

Angle-type snow holders are not highly durable. They will not be able to keep a large amount of snow from coming off. Therefore, these products are used only in those regions where there is little rainfall in winter. In addition, you will need to regularly clean the roof. The cost of such snow holders is 290 rubles / piece. (2 m).

Specificity of tow bars - point snow holders for the roof

Point snow holders are called tows or hooks. They are not designed to hold a large amount of snow, therefore they are used as an addition to tubular and trellis structures. Installation on a soft-roofed roof with a slight slope is allowed.

Related article:

Roofing materials: types and properties, characteristics

Description of the most common roofing materials of various types and types. Application and installation features.

A soft roof facilitates the accumulation of snow, since it has a rough surface in the form of granular dusting. Sediments adhere well to roofing felt and bituminous tiles.

Note! If the roof slopes slightly, snow is unlikely to come off. Nevertheless, for the sake of safety, it is advisable to install staggered yokes with a step of 0.5-0.7 m.

Point snow guards are triangles with a long plate. It is used to fix the product on the battens. The installation of these soft roof snow guards is done so that the plate is located directly under the roofing material. The bitumen shingles laid on top will hide all the fixing points. As a result, the possibility of roof leaks is eliminated. The average price of point stupors is 50-60 rubles / piece.

Snow holders on the roof: installation technology and features of its implementation

Experts recommend installing snow holders together with the roof. In some cases, the installation of snow pads is necessary along the entire perimeter, and sometimes you can limit yourself to only important objects.

These objects include:

- parking area for cars;

- balconies;

- walking paths;

- roof windows.

The installation area is selected taking into account the fact that an avalanche covers a certain area when descending from a roof with a slope of 35 °. As a rule, precipitation falls at a distance of 0.5-1.5 m from the overhang.

Snow holders are installed with an offset of 0.5-0.8 m from the eaves. It is not allowed to place the protective structure directly on the overhang. An exception is the option when the cornice is formed by the roof truss system.

Important! Installing snow pads on or near the eaves will cause collapse.

The cost of products depends on their type, dimensional parameters, material of manufacture, and also the manufacturer. The most popular brands are Borge, Grand Line, Orima.

Average prices of Borge snow guards for different types of roofs:

| Roof type | Price, rub./m. |

| Seam roof | 870 |

| Metal tile | 885 |

| Natural roof tiles | 990 |

| Composite roof tiles | 1070 |

How to properly install snow guards on metal tiles

Metal tiles are the most popular roofing material. Its configuration is conducive to the fact that layers of snow are constantly falling off the roof. A smooth surface is not capable of retaining precipitation. At the same time, the roofing material is sensitive to temperature changes. The metal tile facilitates the melting of snow, due to which the entire layer, together with the ice, begins to slide down. Therefore, the installation of snow guards is mandatory.

The following structures are installed on metal roofs:

- corner;

- lattice;

- tubular.

Corner pieces are suitable for winters with little snow. In other cases, it is better to give preference to lattice and tubular structures. They are robust and easy to install.

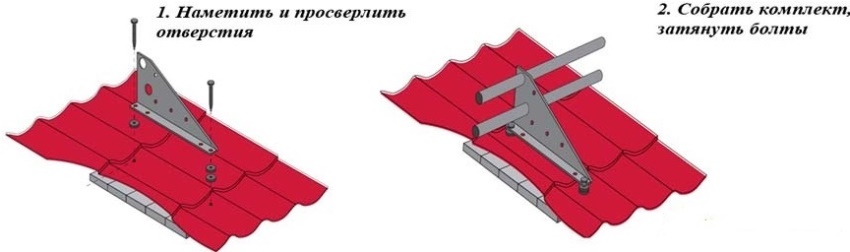

How to install snow guards on metal tiles:

- Marking in the installation area.

- Reinforcement of the lathing structure with an additional bar.

- Assemble the guardrail kit (without tightening the bolts).

- Installation of roofing material.

- Forming holes for fasteners in the bottom wave adjacent to the lathing structure.

- Sealing holes with rubber pads.

- Fixing the bracket to the slope using bolts (0.8x6 cm), taking into account its length and slope. The greater the slope, the tighter the brackets are installed. The optimal step is 0.5 m.

- Installation of pipes in brackets. If the installation of lattice snow holders is carried out, then adjacent structures should be connected to each other.

The fastening of protective products is carried out above the load-bearing wall. In the area of \ u200b \ u200blocating the attic window, the crate is necessarily reinforced. Some snow guards offer additional benefits.For example, for the Monterrey metal roofing there are snow guards with special brackets. They have special projections that allow you not to reinforce the lathing structure.

Important! Installation of lattice and tubular snow guards is carried out through the roofing material.

How is the installation of snow guards on a roof made of corrugated board

Decking has practically the same characteristics as metal tiles. Its surface is smooth and sensitive to temperature changes. The need to install snow guards in this case is due not only to safety considerations. Snow, which melts during the day, freezes in the evening and, sliding off, scratches the corrugated board. As a result, the protective galvanized coating is damaged, which leads to the development of corrosion.

On the roof made of corrugated board, you can install plate, lattice and tubular structures. The latter are used most often, since they are made of galvanized steel and can be painted in any tone of the roofing material.

The installation technology practically does not differ from the procedure for installing snow holders on a metal roof:

- The structure is fixed through the roofing material.

- The lathing is reinforced.

- Fastener holes are sealed with weatherproof rubber gaskets.

Fasteners should be placed at the bottom of the pavement wave, where the corrugated board is adjacent to the crate. Otherwise, the sheet is deformed. If it is planned to install protective structures on the finished roof, to strengthen the lathing, it will be necessary to partially disassemble it. Lamellar or corner products are installed in the upper wave of the profiled sheet. They do not need additional reinforcement of the lathing. The clamps in this case are placed through one wave.

How to install snow guards on a seam roof

On a seam roof, only lattice and tubular snow holders are used as protective structures. The mounting system of the latter differs only in the way of fastening the bracket, which has a specific shape. In this case, the part is fixed directly on the rebate, due to which the roof covering retains its tightness.

Installation of snow guards is carried out using clamps:

- A clip is put on the fold.

- A couple of holes are made (sometimes 3).

- The structure is fixed to the roof using bolted connections.

Protective structures for standing seam roofs are made not only of galvanized steel, but also of copper

The advantage of this technology is that there is no need to reinforce the battens. Installation work is carried out on top of the laid roofing material. As a result, the construction is strong and reliable, since the pressure of the snow layer will be distributed along the fold.

Helpful advice! The size of the step with which the supports are installed depends on the slope of the roof. To get a reliable result, it is advisable to fix them on each fold.

For the manufacture of protective structures for seam roofing, not only galvanized steel is used, but also copper. In the latter case, the products are not sold as a set, but in the form of piece goods. The consumer can purchase an upper and lower bracket, as well as a pipe section. The cost of copper snow guards is quite high, but they fit better with the design of the seam roof, which is also not a cheap pleasure.

Installation of snow holders is possible both at the stage of roofing work and on an already finished roof

Features of installing snow guards on a soft roof

Soft roofs require special handling.The maximum permissible slope angle for such a roof is 15 °. In this case, the likelihood of an avalanche convergence of snow is excluded. For this reason, tubular snow catcher designs are rarely used on soft roofs.

Stone chips on the surface of the pavement hinder the movement of snow and retain precipitation on the roof. On a soft roof, a continuous sheathing is usually used. It is made of sheet plywood with moisture resistant properties, so it does not need reinforcement. Snow protectors are installed at the stage of roofing material installation. Most often, point snow retainers are used, in rare cases - tubular.

The installation technology of tubular structures is the same as in the case of installation on metal tiles or corrugated board. Although this system has a drawback, since the fasteners are located on top, thereby breaking the tightness of the coating.

Mounting technology for stoppers and triangular clips:

- Products are placed in 2-3 rows in a checkerboard pattern. Installation step - 0.5-0.7 m.

- The yoke is fixed to the batten structure so that the next soft mat can overlap the mounting plate. In this case, the triangular part of the yoke remains outside (over the roof).

- The snow holder is fixed with self-tapping screws.

If the roof has been installed previously, point snow guards can be installed from above. In this case, the use of weather-resistant rubber gaskets is mandatory.

DIY technology for creating snow holders on the roof

The installation of snow-retaining structures on the roof is accompanied by a number of advantages. These simple devices have many advantages.

Snow catchers perform the following functions:

- protection of roofing materials and drainage system from damage;

- effective elimination of heavy snow caps, which can cause deformation changes and roof deflection;

- preventing the appearance of water smudges on the ceilings of the premises located on the upper floors of the building;

- protection of decorative elements and plantings under windows;

- protection of cars parked near the building from snow melting;

- protection of external plaster, which can deteriorate with melt water if there is a sharp warming.

Helpful advice! Even if there are snow catchers on the roof, it is advisable to clean the roof on a regular basis (once every 1-2 weeks). To eliminate the need for this event, a heating cable can be laid under the roof. Thanks to him, the snow will quickly melt and flow down the drain without lingering on the roof.

Recommendations for the manufacture of corner snow catchers on the roof

In order to save money, you can independently make corner-type protective fences and install them on the roof. This option is considered the easiest to implement.

This will require the following tools and materials:

- scissors for metal or a hacksaw;

- sheet stainless steel with polymer spraying;

- bending machine;

- ruler and marker for marking;

- drill.

To begin with, a drawing with dimensions is selected. On its basis, a template for a corner snow holder is created. After that, using a ruler and a marker, the markings are transferred to the sheet steel. This should be done so that as little waste as possible remains after cutting.

In accordance with the marking, metal is cut using a hacksaw or scissors. You should not use a grinder for these purposes, even if the master has good experience in handling it.As a result of cutting with this tool, the protective coating on the metal is damaged, which prevents corrosion.

At the next stage, the workpiece must be fixed on the desktop. Using a listogib, bend the product along the marking lines. The result should be a corner with two shelves for fasteners, the height of which is 15-20 cm. Self-tapping screws will be used to fix the snow holder. Holes should be made for them in the mounting shelves.

Corner structures are mounted in a checkerboard pattern. If the length of the slope is less than 4 m, it is enough to install the snow guards in two rows. If this figure is 6 m or more, at least three to four tiers of barriers will be required.

Manufacturing technology of lattice snow holders on the roof of a private house

Lattice structures are more difficult to manufacture than corner structures. This will require skills in handling a grinder and a welding machine.

List of required tools and materials:

- metal corner;

- stainless steel to create a lattice;

- Bulgarian;

- metal pipes of a suitable diameter;

- welding machine;

- suspended supports;

- building level.

First, a drawing is drawn up. He must take into account the parameters of the roof and all related factors. A corner should be used to make the grille frame, and pipes should be used as an amplifier. Steel is prepared, markings are applied over the material. After that, using a grinder, all the details are cut out.

Place the corners so that you get a rectangle. After that, you can fix the upper part of the frame by welding. It is very important to ensure that there are no distortions. If there are no defects, you can weld the corner parts of the frame. Then the pipes are fixed. They should be positioned vertically in relation to the corners and welded. Having made the required number of structures, you can proceed to their installation. You must first install the suspension supports on the roof.

Supports for self-made structures, as well as for factory-made snow guards, can be purchased at a hardware store. By using these simple devices, many of the problems associated with snow avalanches can be avoided.