One of the prerequisites for comfort and coziness in the kitchen is its cleanliness. In order to minimize the accumulation of unpleasant odors and contaminants both on furniture and in the air, it is necessary to purchase special equipment. The main assistant is a ventilation hood. It is very important to choose and install it correctly. The exhaust system also affects the efficiency of work, therefore it is necessary to choose the right pipes for the hoods.

Content

- 1 The use of ventilation pipes for hoods in the kitchen

- 2 Pipes for ventilation: selection features for the exhaust and ventilation system

- 3 Installation of a hood in the kitchen: is it possible to do without it

- 4 Classification of ventilation pipes for exhaust

- 5 Hood pipes: tips and tricks for choosing

- 6 How to properly install a hood in the kitchen for all types of pipes: general recommendations

The use of ventilation pipes for hoods in the kitchen

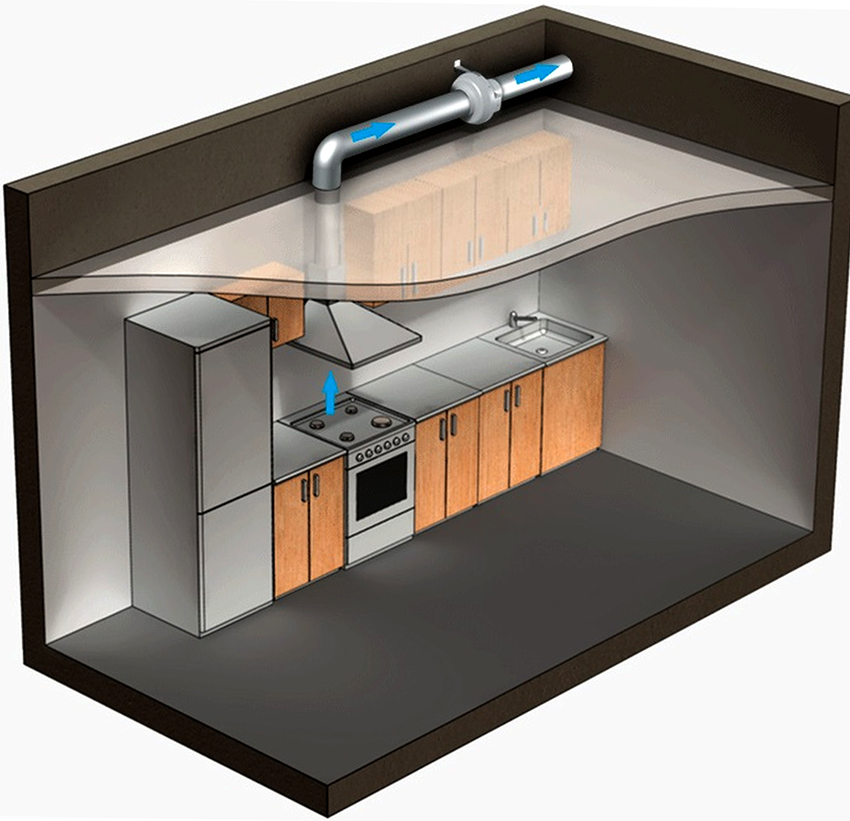

The key to a beautiful and cozy kitchen is its impeccable cleanliness. Regular cleaning and clean air are important. Ordinary ventilation is not enough here, as during cooking, moisture and combustion elements are released, which are deposited on the walls, ceiling, floor and furniture. A ventilation hood will largely help solve this problem. This appliance requires proper installation, especially at the connection to the ventilation duct. By choosing the right pipe for the hood, it will be possible to significantly increase the ventilation efficiency.

Any residential building must be equipped with a hood. This is the most important condition not only for comfortable but also safe living, since people themselves emit carbon dioxide and moisture when breathing. In addition, decay products such as soot, grease, gases and moisture appear during cooking.

As a result, moisture settles on furniture and walls, forming mold, fumes and soot that contaminate surfaces, and combustion elements such as carbon dioxide lead to fatigue, irritability of the respiratory system, deterioration of well-being and decreased performance. Frying carcinogens can cause food poisoning. That is why it is important to install a hood, the efficiency of which is largely influenced by correctly selected pipes.

Evolution and development of kitchen hood ducts

In the high-rise buildings built during the Soviet era, the apartments had a small area. Ventilation in such rooms took not only harmful substances from the kitchen and bathroom, but also air from living rooms. The ventilation ducts were then built directly into the walls of buildings. In the houses of individual buildings, ventilation was not provided at all, and an ordinary chimney built into a home stove saved residents from the harmful effects of carbon dioxide. The products of fuel combustion and decay elements formed during cooking escaped there.

Useful advice! Before purchasing a hood and ventilation pipes, it is necessary to study the ventilation or exhaust system itself, which is provided for by the building structure. This is an important factor contributing to the efficiency of room air purification.

As a rule, the exhaust duct is not enough, therefore an extractor hood with an air duct is additionally installed

Fresh air in old houses and apartments was supplied mainly through loose doors and windows, and carbon deposits and soot gradually accumulated on the walls and ceiling, so whitewashing was required every year. In some apartments, ventilation ducts were provided - prototypes of kitchen hoods, the same ventilation was installed in bathrooms and toilets.

In modern apartments, in addition to the hood, an additional ventilation system is installed. It can be exhaust and supply and exhaust. In energy-efficient homes, the installation of a supply and exhaust system with heat recovery is a must.

Pipes for ventilation: selection features for the exhaust and ventilation system

A conventional cooker hood is a forced draft ventilation system that is almost identical to ventilation. But it is worth noting the difference from general in-house ventilation. It lies in the fact that in multi-storey buildings, general ventilation with natural impulse functions without using the fan. In addition, a system of this type serves to carry out air exchange throughout the room, and the exhaust function assumes the removal of polluted air at a specific place and at a specific time.

An air duct is very important for the kitchen. Modern general ventilation does not eliminate combustion products and moisture evaporation from the stove, but provides air exchange throughout the apartment. This situation does not suit everyone, since everyone wants the repairs to last as long as possible, so that they do not often need to carry out general cleaning with thorough washing of walls, ceilings and furniture.

Therefore, over time, they began to produce local ventilation devices that are installed above the stoves - hoods. The pipe for the kitchen serves to remove the polluted air outside the room. This is the main function of air ducts.

Like any device, the duct has its pros and cons. The main advantage is the ability to effectively remove carbon dioxide, moisture and soot. Disadvantages of exhaust pipes:

- take up a lot of space;

- do not fit well into the kitchen interior;

- fan operation creates additional noise, especially if its installation was carried out incorrectly;

- regular cleaning is required outside and sometimes inside the product.

Installation of a hood in the kitchen: is it possible to do without it

It is not always possible to install a cooker hood in the kitchen. There are times when its installation is prohibited according to the rules for the operation of gas appliances. For example, if a gas water heater is installed in the room, the so-called gas water heater, or a gas boiler for heating with an open-type combustion chamber, it is contraindicated to mount a circulating hood.

Useful advice! Removal of decay products from the boiler occurs without coercion, and when the fan is turned on at the hood, the draft may overturn, which will lead to the release of poisonous combustion products into the apartment. Therefore, the installation of a flow-through exhaust device is allowed only if the boiler is installed with a closed firebox, that is, with a coaxial chimney and combustion air intake from the street. It is possible to install a circulating hood with filters that remove grease and fumes from the air.

Therefore, before making a hood in the kitchen, you need to figure out if you can do without an air duct. If you still need it, then you should decide on the type of device. Hoods can be flowing or circulating. Flow-through devices extract exhaust air from the kitchen, and circulation devices simply purify the air without eliminating it.

Circulating devices are installed above the stove, air passes through special carbon filters, and fat is removed there. For such designs, air ducts are not required, they are compact and easy to install. The main disadvantages of a hood without an air duct are the need to frequently change filters, incomplete air purification, and the lack of moisture and carbon dioxide removal.

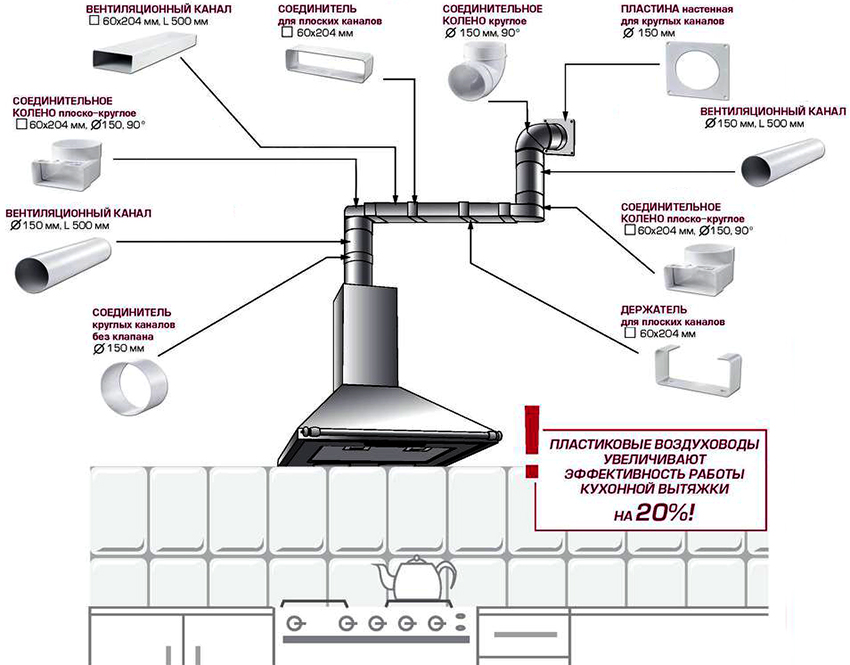

Classification of ventilation pipes for exhaust

The modern market offers the widest selection of ventilation systems and accessories for them required for installation. At the same time, there is a certain classification of air ducts. Exhaust pipes in a private house or apartment, intended for household ventilation, are conventionally divided into the following groups:

- Depending on the material of manufacture, there can be aluminum, plastic pipes for ventilation, as well as made of galvanized steel.

- According to the shape of the duct, square, rectangular or round pipes are distinguished.

- Taking into account the degree of flexibility, two types of products are distinguished - flexible and rigid boxes.

Flexible air ducts are usually made of corrugated aluminum or galvanized steel. Now rigid pipes made of metal are not used, since their installation is quite complicated, like the manufacturing process itself. Such pipes should have a diameter of 100-150 mm. Aluminum products are much more expensive, although they do not have special qualities and advantages. Therefore, they are not used when installing a kitchen hood.

Plastic air ducts are round, square or rectangular. Their surface can be either rough or smooth. Most often they are white, although they are often painted in other colors, which makes it possible to choose a plastic duct for a kitchen hood that will harmoniously fit into the interior.

We will talk in more detail about each specific type of air duct below, list their advantages and disadvantages, and also dwell on the installation features.

Useful advice! Plastic ventilation pipes are considered the most practical, as they are easy to clean thanks to their smooth surface, and much less grease and soot collects inside. The smoothness of the walls also helps to reduce air resistance, resulting in less vibration and noise.

Materials for the manufacture of plastic ventilation pipes

Plastic pipes for hoods can be made from different types of material, the main ones are as follows:

- polyvinyl chloride;

- polyurethane;

- polypropylene;

- polyethylene.

The most practical and common are PVC pipes. Among the advantages should be highlighted ease, affordable price, ease of installation. In addition, they provide good strength and tightness to the plastic hood.

At the same time, it is worth noting certain limitations in the use of these pipes.In particular, their use is not allowed at temperatures above 120 ° C, since when heated, toxic chlorine is released, which can cause irreparable harm to health. Pipes of this type can be installed in the kitchen, bathroom and toilet, but their installation in rooms with high temperatures, for example, in a sauna or in a room with a fireplace, is unacceptable.

At temperatures below 5 ° C, the effectiveness of pipes is lost, polyvinyl chloride becomes more fragile, so this material is not suitable for installation in premises that are intended for seasonal living.

Polypropylene is an excellent dielectric, has low hygroscopicity and high resistance to aggressive chemical environments. The polypropylene plastic ventilation duct is about 4 times stronger than HDPE pipes. However, it can be used at temperatures that do not exceed 90 ° C, with the exception of the fire-resistant model with flame retardant additives - PPS.

Polyurethane is similar in properties to PVC pipes, but can withstand higher temperatures - up to 280 ° C. The most durable material for making plastic pipes is vinyl urethane, which is reinforced with a steel spiral. It should be noted that with proper operation, plastic pipes will last more than 10 years.

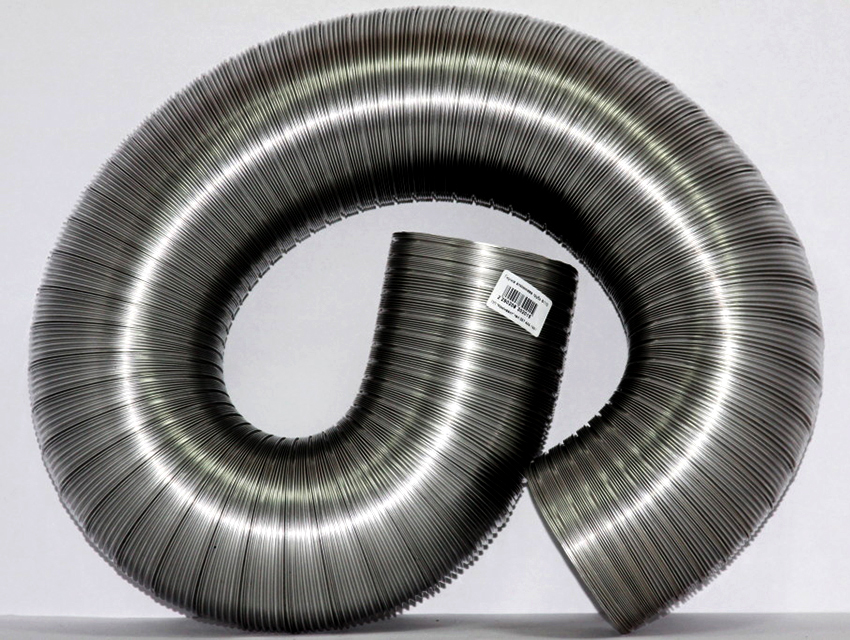

Metal air ducts and corrugations for hoods

Among the metal pipes for hoods, the most popular are aluminum corrugations for ventilation with a circular cross section. They are practical and easy to install, as they can take almost any shape. No turning parts are needed for installation, just bend the pipe. In addition, aluminum air ducts are durable.

The main disadvantage is that, due to the corrugated surface, it is difficult to remove the settled fat and soot from them. In addition, the corrugation creates a certain resistance to air, which leads to the formation of additional noise.

The corrugation of the hood can be made of galvanized steel. These pipes are stiff and strong, and easy to install (like aluminum corrugation), but the stiffness makes the process a little difficult. At the same time, it should be noted that in places where the zinc spraying is damaged, the pipe corrodes.

Useful advice! Corrugation made of aluminum is considered more plastic, since it can be easily bent, stretched or compressed. It is this type of duct that is recommended for use in places with turns and drops.

Aluminum and galvanized metal air ducts have common advantages:

- additional adapters and corners are not required for installation;

- it is smooth bends, not sharp bends, that increase ventilation efficiency;

- the ability to stretch and compress greatly simplifies the installation process;

- low cost.

Hood pipes: tips and tricks for choosing

When choosing pipes for an air duct, most consumers are primarily guided by aesthetic considerations, which is quite justified. Therefore, before buying, it is recommended to determine exactly how the box will be mounted: outside or behind furniture, behind a false wall or above a false ceiling.

A shiny corrugated pipe definitely spoils the interior of the kitchen very much, so if we are talking about an open location, then most often they choose smooth plastic pipes that can be painted in a color that matches the design of the ceiling or walls. A rectangular or square pipe for the kitchen fits most beautifully into an open interior. A round hood is less aesthetically pleasing, but it creates minimal resistance to air flow, minimizing noise.

Related article:

Exhaust corrugation: ease of installation and ease of use

Advantages and disadvantages, scope. Materials of manufacture and classification, advice on selection. Features and installation procedure.

If we are talking about a hidden method of laying, then it is better to give preference to a corrugated metal pipe. It is much easier to mount, since no adapters and angles are required. If it is necessary to overcome an obstacle on the way to the ventilation duct, it is enough to simply bend such a pipe. However, additional costs will be required to mask corrugated products. In addition, if access to the duct is required, then the entire conspiracy will have to be dismantled.

Forms and sizes of ventilation pipes: selection rules

The diameter of the round ventilation pipes should correspond to the section of the outlet on the kitchen hood. It should be remembered that it is the round ducts that create the minimum resistance to the air flow. As for the shape, a straight pipe is optimal, however, sharp corners are not allowed when installing the air ducts.

The ideal duct length should be no more than 3 m. If this figure is higher, then the fan must be of maximum power. The diameters of the corrugation used in household ventilation are 10, 12.5 and 15 cm.

Standard sizes of plastic pipes for ventilation of square and rectangular shapes are as follows: 8 × 8, 10 × 10, 12.5 × 12.5, 5.5 × 11, 5 × 12, 6 × 20.4 and 9 × 22 cm.Diameter plastic pipes can be 10, 12.5, 15 and 20 cm.

Useful advice! Choosing between plastic and metal products, it is better to give preference to a plastic hood for the kitchen. Such pipes have a lower resistance to air flow, they are easier to wash, and they fit much more naturally into the interior. If a concealed ventilation duct installation or operation at high temperatures is expected, then it is recommended to use flexible pipes.

How to calculate the minimum dimensions of a plastic pipe

The cross-section of square and rectangular plastic ventilation pipes should be equal to the cross-sectional area of the round exhaust pipe. If the diameter is narrowed, the system performance will deteriorate, the fan will be overloaded, and the noise will increase. As a result, vibration will occur and the fasteners will weaken. The minimum section size is allowed only when a powerful fan is installed in the hood, but at the same time it is not used to the maximum.

It is best to take a pipe with a cross-section slightly larger than the diameter of the pipe. If the pipe diameter significantly exceeds the cross-sectional area of the nozzle, this will entail additional costs and problems with its masking.

You should not calculate the size of the section of the hood box. It should be equal to the diameter of the outlet. If the hood has a certain power reserve, but at the same time it is not used at full capacity, then the section can be slightly narrowed. The formula will help to calculate its minimum value:

Smin = Sр * (Qр * Qmax), where:

Smin is the minimum cross-section indicator;

Sр - branch pipe section indicated in the product passport;

Qр is the volume of air to be removed;

Qmax - the maximum indicator of the volume of air to be removed, it is indicated in the hood's passport.

Qp is calculated by another formula: Qp = Vkitchen * 12 * 1.3 m³. Vkuhni is the area of the room. According to sanitary standards, 12 is an indicator of air exchange, that is, the air in the kitchen should be changed 12 times per hour. 1.3 is the coefficient of power loss in the duct and ventilation shaft.

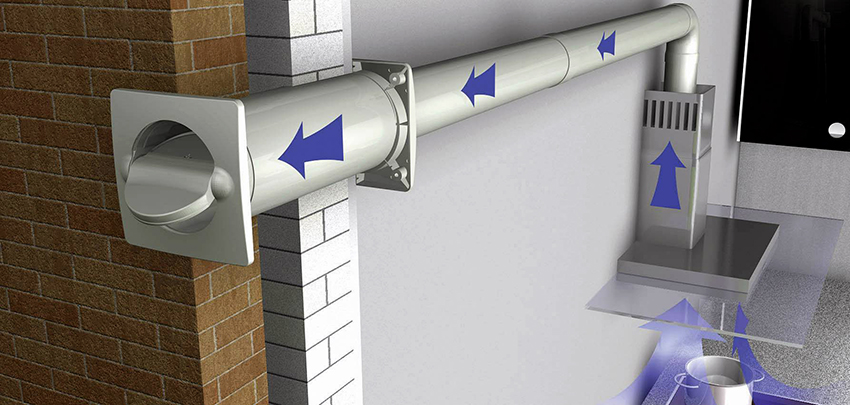

How to properly install a hood in the kitchen for all types of pipes: general recommendations

First of all, it is necessary to ensure thorough sealing of the joints at all possible joints of the pipe and transition parts.In this case, the number of adapters should be minimal, as should the number of turns and contractions. All these factors entail a decrease in the efficiency of the hood.

The box must be securely attached to the wall and ceiling. For this purpose, special clamps are used. If the air duct is movable, then vibration will occur in the system, which will lead to an increase in the noise level and a violation of the sealing.

In order to find out how to properly install the hood, first of all, you should study the rules for installing the air duct, that is, laying the pipe from the hood to the opening of the ventilation shaft. To do this, you must choose the shortest possible path. In the event that the length of the structure exceeds 3 m, it is worth considering another version of the air outlet, for example, directly to the street.

The system itself should consist of a minimum number of turns, since each turn of the box by 90 ° reduces the efficiency of the hood by about 10%. Such losses can be avoided by organizing a smooth pipe rotation using two 135 ° bends or bends with different angles.

Important! In no case should the duct turn at an acute angle - such an incorrect step will lead to a complete stop of air movement in the pipeline.

In the event that the length of the duct is excessively long, it is better to resort to the help of specialists who will help to calculate the expected power losses in the pipe and the required fan power.

How to lay a plastic ventilation duct with your own hands

The very process of installing the air outlet pipes from the hood to the ventilation duct is a simple task, so it can be done independently without having some experience. To do this, just follow the tips below. First you need to prepare tools and materials, which should include:

- box;

- corners, adapters of a certain section;

- bends;

- return valve;

- lattice for connecting ducts to the ventilation shaft;

- drill;

- hacksaw;

- Bulgarian;

- screwdriver;

- sealant.

In order to install an indoor cooker hood duct, the complete air path should be carefully measured. The grate located at the entrance to the mine must be dismantled. The channel itself needs to be cleaned of dust, burning and cobwebs. After installing the hood, it is necessary to connect the box to the exhaust pipe. In this case, all joints should be coated with sealant. In this case, a heat-resistant agent is not needed, since the temperature of the air that is removed is low.

Next, the system is sequentially installed. To do this, one element is inserted alternately into another, and the pipes are shortened to the required size, cutting off the remains with a grinder or a hacksaw. Then the box is fixed to the wall using special fasteners or clamps. The distance between them should not exceed 500 mm.

The lattice is installed on the shaft wall using dowels. A grille with a hole for a pipe and for natural ventilation is considered more practical. The system should also be equipped with a non-return valve that will prevent air from the ventilation shaft back into the room if the hood fails.

System testing, pipe insulation and hood masking

The system must be tested before use. If a leak is found, the defective areas are lubricated with a sealant. In the event of a rattling noise at the points of contact of the duct with other structures, a polystyrene or foam polyethylene gasket should be placed.

If the system is installed in the attic, then it is necessary to insulate the ventilation pipe.It is also necessary to exclude the possibility of water getting into the air duct, as this will lead to a quick failure of the fan. Thermal insulation will help to avoid such consequences. For this purpose, it is sufficient to use boards made of foamed polyurethane foam or mineral wool. A layer of insulation should be covered with roofing material or fiberglass, securing everything with wire.

Useful advice! For an efficient installation of the air duct, it is necessary to use only industrial pipes, adapters and adapters for the exhaust duct. The modern market offers a wide selection of these products, both for round hoods and for square and rectangular boxes.

In order to mask the air duct, you can use different methods:

- decorative screen;

- imitation kitchen hanging cabinet;

- stitching a structure into a suspended ceiling;

- painting or decorating pipes to match the walls and ceiling;

- installation of decorative boxes.

Masking with a screen that simulates a wall is the most popular and budget option. For this, you can use a simple drywall. In the case of installing boxes behind a false wall or under a false ceiling, it is necessary to take into account the fact that it will be problematic to disassemble the structure in the future.

How to properly make a hood in the kitchen without a box and other ways to organize an air duct

Circulation hoods constitute a special category. They are more compact and easier to install as they do not require duct installation. The hood without pipes is simply fixed on the wall or fixed to the ceiling if the stove is located in the middle of the kitchen.

In addition to the traditional method of diverting the air duct into the ventilation duct, as well as installing hoods without pipes, there are other options for air exhaust. It is possible to connect one or two air outlet points to the duct at the same time, or simply bring the pipe outside. Whichever method you choose, the main thing is that general ventilation is installed in the kitchen.

If the kitchen is made in a loft style, then the duct can become part of the interior and does not need masking

If you plan to install one intake point, then when connected to the ventilation system, it should be possible for natural ventilation to function. If there are two ventilation ducts in the kitchen, then it is necessary to connect the hood to one of them, and leave a passage in the other shaft for natural air exchange.

When there is only one mine, a tee is mounted at the inlet of the exhaust pipe to the ventilation shaft with the option of switching between a forced exhaust system and natural ventilation. If you need to connect two air intakes at once to one ventilation system, then check valves must be installed between the tee and the fans. Otherwise, the fans will simply interfere with each other's work.

In the efficiency of the ventilation system in the kitchen, a significant role is played by the hood itself, the methods of air removal, as well as the air duct. When choosing pipes for exhaust, it is necessary to take into account the material of manufacture, their shape and dimensions of the ventilation duct. If everything is selected correctly, then, following the advice given in the article, you can easily independently connect the hood in the kitchen.