Doors made of aluminum, in comparison with wooden counterparts, have many advantages. Their strength is higher and moreover they are more resistant to moisture. An aluminum door is a versatile design that can be purchased at a relatively low cost. There are several types of such doors. Each of them corresponds to certain operating conditions.

Content

- 1 Advantages and disadvantages of aluminum doors: photo

- 2 Features of interior and exterior aluminum doors with glass

- 3 Varieties of aluminum doors, depending on their design

- 4 Aluminum doors with glass: materials of manufacture

- 5 Special types of aluminum doors: fireproof and other types of products

- 6 Aluminum door: features of entrance structures

- 7 Internal aluminum doors: characteristics and tips for choosing

- 8 Aluminum profile doors: the most common colors

- 9 DIY aluminum door installation: opening preparation

- 10 Aluminum door repair and adjustment: tips

- 11 Overview of prices for aluminum doors: interior and exterior

Advantages and disadvantages of aluminum doors: photo

The range of aluminum doors is incredibly wide. These products have gained popularity due to their versatility and other positive qualities. Before purchasing such a canvas, it is recommended to pay attention to its advantages and disadvantages.

The main advantages of these structures are ease of manufacture and low cost of parts that are used in the production process. Today you can find products that have various shapes, which contributes to the expansion of their operational scope. You can order a profile door on one of the websites that sell them, or purchase a ready-made structure in a profile store. It is possible to place an individual order for an entrance door of a non-standard size.

Another advantage of such products is the variety of opening options. The materials used in the production of aluminum doors have a long service life and are resistant to low temperatures, moisture and mechanical stress. Of course, the strength of such a cloth is lower than that of its metal counterparts. However, it is sufficient to provide good resistance to normal operating conditions.

Entrance and interior aluminum doors can be repaired in case of breakage, as their design contributes to this. It should also be noted that such products are distinguished by their presentable appearance and have a high degree of tightness. Removing dirt from the surface of such a canvas is quite simple. Materials from which such doors are made, resistant to chemical agents. It should be emphasized that such canvases have a high degree of sound insulation.

Note! Experts recommend installing aluminum doors and windows in apartments that are located in close proximity to busy highways and airports.

Aluminum structures are highly environmentally friendly and do not emit harmful substances that can harm human health. Entrance groups of this type have good fire resistance. Most of these products belong to the G1 flammability class. They prevent the spread of fire and do not emit harmful substances when heated.

Like any other product, aluminum entrance and interior linens have their drawbacks. Experts recommend that you familiarize yourself with the list of shortcomings in advance in order to understand the advisability of purchasing this type of door for a specific situation. The main disadvantages of these products are considered to be their rather large mass and the frequent need to order according to an individual drawing.

Features of interior and exterior aluminum doors with glass

Aluminum canvases differ from each other in geometric characteristics and stylistic performance. The main features by which these products are separated are their thickness and color. Design features are also considered very important, since the number of doors and the way they are opened depend on them.

Manufacturing technology of aluminum doors eliminates gaps. The profile elements that are used when making such canvases may differ in their geometric and physical characteristics, depending on the operational accessory of the product.

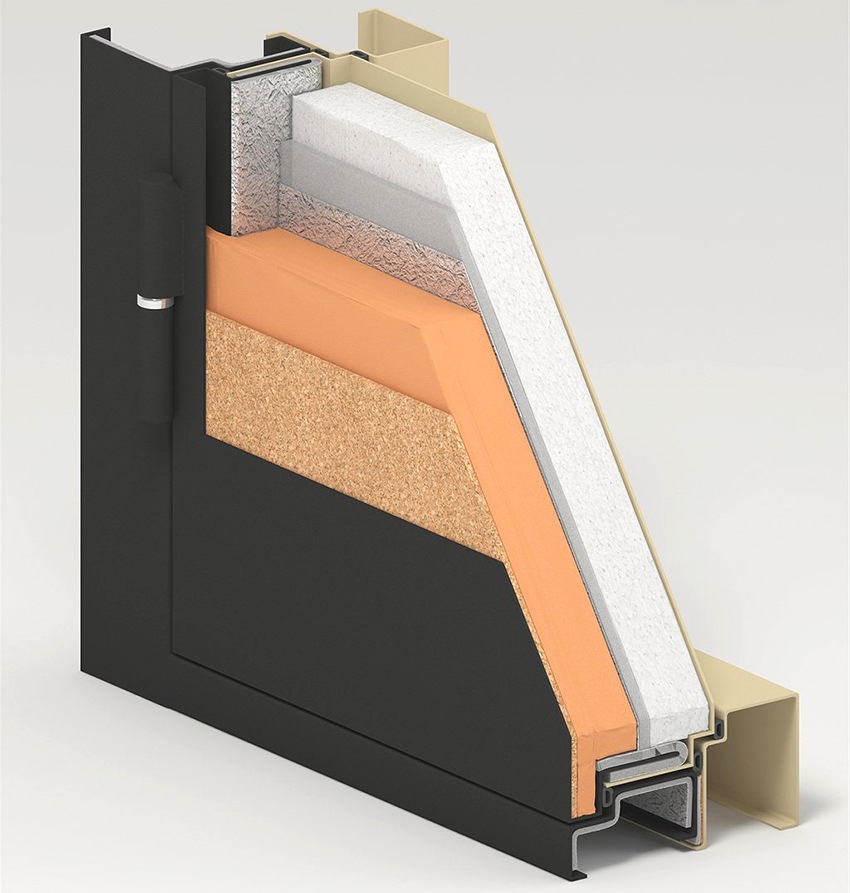

In the case of installing an aluminum sheet at the entrance to a room that is heated, a prerequisite is the presence of a thermal break. This property is possessed by the material, the layer of which is used in these canvases to increase the hermetic qualities. This minimizes thermal leakage.

If a thermal insulating material is used in the door structure, its mass increases. With an increase in the weight of the canvas, it becomes necessary to use more durable and stable reinforcement. Before purchasing such a design, it is recommended to study the state standards governing such products. GOST of aluminum doors contains information on the characteristics that a high-quality canvas that meets the standards should have.

It should be noted that the door structure also includes special sealing elements. They are located in areas that are most vulnerable to low temperatures. Sealing parts increase the soundproofing of the door and also increase its service life.

Aluminum canvases with glass inserts

Most aluminum canvases include glass inserts in their design. The size of the glass is selected when ordering an aluminum door. Glass can be made from different raw materials (depending on operational needs). The polymer material that is present in the aluminum profile structure must comply with environmental standards.

Note! If you want to purchase a reliable and high-quality design, it is recommended to pay attention to the weight of the canvas. The weight of such a product varies from 100 to 120 kg.

Varieties of aluminum doors, depending on their design

These canvases can be of various designs. It all depends on the operating conditions. First of all, there are several options for opening such doors. These products are differentiated on this basis.

Swing doors. They are the most common type and are used in residential and office buildings as interior structures. Opening in this case occurs in one direction (left or right). The definition of the side depends on operational factors and the location of the locking elements.

Sliding canvases. They differ from aluminum swing doors in that they do not open towards the street or premises, but linearly. They are equipped with a special mechanism that includes aluminum profiles, carriages, rollers and clamps. The use of such doors can significantly save usable room space. They are popular in small apartments.

Folding structures. They are used in both cold and warm groups. It should be said right away that such doors are in most cases mounted indoors. Their location at the entrance to a building or apartment is impractical.

Pendulum products. Aluminum canvases of this type are installed in cold entrance groups. They have a non-standard opening method - two-sided. Swinging in two directions increases the passage area. Most often, ready-made aluminum doors of this type are mounted in office buildings.

Revolving doors. It is customary to install this type of product at the entrance to administrative institutions, airports, and universities. They have a rather complex design. In this case, the passage of people is carried out by moving the door around its axis. They are not installed in apartments due to their bulkiness and high cost. The number of leaves in such a design ranges from 2 to 4.

Helpful information! Revolving entrance doors can be automatic.

Among other things, sliding doors are classified according to the location of the sashes. Depending on this indicator, two types of structures can be distinguished. The first option has sashes that move in the same plane when plowing. The second type of door opens a little differently: one of the leaves moves off and becomes in a parallel position on the profile, after which it rolls back.

Heat resistance classification of aluminum glass doors

All aluminum structures that can be found on the market today are divided into two groups depending on their thermal properties. The first group is conventionally referred to as cold, as it includes models without a thermal insert. These products are installed in cases where there is no need to keep heat indoors. The second group includes doors equipped with insulation. Let's consider their features in more detail.

Cold. As a rule, such models are mounted between rooms inside a building. Cold aluminum doors do not contain a thermal insert, therefore they cannot provide heat retention inside the room. In some cases, this may be an entrance group. An example is the structures installed in stores.

Cold canvases are versatile and have a different number of chambers in a glass unit.Many of these designs consist of only one glass, which is tubeless. The sash in such products is characterized by small dimensions and low weight. From the point of view of designers, these canvases correspond to different styles, which increases the demand for them. It is important to remember that cold aluminum structures used indoors and at the entrance can be fitted with seals. The advantage of such doors is their simplicity.

Warm. Such models are usually used as an entrance group. This is due to the fact that warm aluminum doors have insulating qualities. The peculiarities of their structure make it possible to effectively cope with the delimiting function. Such canvases are able to provide protection against the penetration of cold air into the room, since there are special sealing elements in their design. The canvas most often consists of three air chambers.

Helpful information! An aluminum profile equipped with a thermal break protects the room inside the building from cold air. The number of glass chambers may vary, but the most popular are two-chamber and three-chamber canvases. Such designs are great for the domestic climate, especially for the northern regions.

Separately, it should be said that warm aluminum doors with glass are produced together with a special threshold. The function of the threshold is also to retain heat inside the room. It is impractical to use such canvases to delineate rooms.

Aluminum doors with glass: materials of manufacture

Modern industry is constantly evolving, which contributes to the emergence of new materials, easy to manufacture, with increased strength and versatility. Aluminum door leaves have glass that can be made from different materials. There are many options for glass inserts in such designs.

Double-glazed window. Standard insert option that includes one or more cameras. Single-chamber double-glazed windows consist of two glasses and a space that is located between them. In turn, the two-chamber design has three glasses and two gaps.

Triplex. In aluminum canvases, a three-layer version of a triplex is used - 2 glasses, fastened together with a film of polymer material. This protective shell has a very important function: it prevents glass from shattering on impact.

Strained glass. One of the most reliable options for an aluminum door. In this case, glass has an increased strength index due to the fact that it underwent heat treatment during production. A significant disadvantage of hardening is that after hardening, the product absolutely cannot be processed with cutting tools, drilled, etc.

Note! The materials used for the manufacture of glass in door leaves can be both traditional and non-standard. Silicate glass is the classic option. Non-standard options include organic and polycarbonate glass.

Reinforced glass. Like the previous version, it has high strength characteristics and resistance to mechanical stress. The impact resistance of this glass is due to the presence of a special film. In some cases, the reinforcement is done using thin metal threads.

Related article:

Wooden entrance door for a private house and apartment: reliability and design

The difference in designs and modes of operation. Self-made and installation tips. Repair, restoration and design processing.

Glass decorative characteristics: existing options

Glazed aluminum doors are classified according to their decorative characteristics. The glass in the canvas can not only differ in design, but also correspond to different styles. The following glass options are found in modern metal doors:

- transparent;

- tinted;

- photochromic.

Helpful information! Transparent glasses are most often used in aluminum structures. However, such elements do not protect from prying eyes and sunlight.

The price of aluminum doors with tinted glass is higher than the cost of conventional counterparts. However, this solution allows you to limit the room from prying eyes. Moreover, such products transmit sunlight well. Today, two types of tinted glass are distinguished:

- with vinyl film;

- painted.

Photochromic products are perhaps the most technologically advanced. Their cost is quite high, which is due to the design features. Photochromic glass is a triplex, in which a special substance is placed between two circuits that allows electricity to pass through. The working principle of this glass is based on molecular motion. When the electricity is on, the molecules between the two glasses take the necessary positions to allow light to pass through. And when the power source is turned off, they are located chaotically, thereby preventing the penetration of light into the room.

Special types of aluminum doors: fireproof and other types of products

Doors with aluminum profiles are commonly used in various office buildings. It is also customary to install them in buildings that are visited by a large number of people every day. However, from the whole variety of aluminum doors, several groups can be distinguished that have a narrow specialization:

- fireproof;

- armored;

- increased protection.

In the first case, a solid aluminum sheet is most often used for the production of a door leaf, however, glass elements can also be found in such structures. An entrance group made of aluminum of this type is divided into several types, depending on the design:

If an aluminum door is installed at the entrance to a heated room, it must be equipped with a thermal break

- solid;

- partially glazed;

- glass.

Armored doors are used in cases where it is necessary to provide maximum protection for the premises. Products that have increased strength and protective characteristics are used in places with high traffic of people. These can be hospitals, supermarkets, hotels, etc.

Aluminum entrance doors made of aluminum profiles are characterized by high environmental friendliness and are hypoallergenic. Thus, they are great for healthcare facilities. In addition, they are often installed in hairdressing and beauty salons. An entrance group of this type is not uncommon in apartment buildings. In this case, rather massive structures are used, which are highly durable and are capable of protecting the entrance from the penetration of unauthorized people.

Aluminum door: features of entrance structures

The design of the aluminum profile sheet includes several constituent elements. The principle of operation of such doors may be different, however, different entrance groups have a common structure, which is due to their operational affiliation. Consider what elements the front doors include.

The design is based on the door frame.Such a profile, depending on the purpose of the canvas, can have a different thickness. The minimum figure is 75 mm.

Note! The door frame consists of chambers. The number of chambers varies based on the operational accessory of the structure - from 5 and more.

The canvas is a frame that contains a profile equipped with sealing elements. The thickness of this aluminum profile for doors is on average about 50 mm. The number of chambers in such a canvas can be different. The minimum number of bays is 3 and the maximum is 5.

One of the most important elements of the door is the lock. The design of the locking elements may vary. There are simple locks and more complex options. From unpretentious structures in aluminum doors, it is recommended to use crossbar locking elements with several points of fastening the leaf. For entrance groups, the best solution is a mortise lock.

Auxiliary fittings include hinges on which the door leaf is mounted. The minimum quantity of these products is 2 pieces. Structures installed on 3 hinges are much less common. Typically, this number of elements is used when it is necessary to increase protection. And also 3 hinges are installed when a heavy aluminum entrance door is installed. The price of this design is higher than the cost of standard analogs.

For an entrance group, an excellent solution is to purchase internal hinges. It is almost impossible to break such loops, since they have a hidden location.

The door structure includes double-glazed windows. Their thickness depends on the number of chambers. The most common are double-glazed windows, the thickness of which is 24 mm. The 32mm version is also popular. Among the remaining accessories, it is worth noting the following components: a handle and a peephole. Aluminum door handles come in a variety of shapes.

And finally, the last element of the door structure is the threshold. It is only necessary when it is necessary to increase the thermal protection. The thresholds are made of profiles and include sealing parts.

How to choose an aluminum entrance door: recommendations

Before purchasing an entrance door from this material, you need to pay attention to some of the nuances that allow you to make the right choice. First of all, it should be borne in mind that some unscrupulous manufacturers use a window profile for the manufacture of entrance and interior paintings. In terms of its technical characteristics, such a design is significantly inferior to the door type, so you should be careful and take into account the thickness and weight of the product.

Helpful information! Experts advise choosing a company that will manufacture doors, according to reviews on the Internet. This will avoid cooperation with unscrupulous manufacturers.

When choosing an interior design, it is recommended to pay attention to doors with an aluminum edge. Such canvases, as a rule, have increased wear resistance and last several years longer.

Another factor that allows you to assess the quality of the door before purchasing it is the color of the door leaf. Factory processing excludes the presence of smudges and roughness, which is not difficult to determine. Low-quality products are cheaper, but you should not save on buying this design. The price of an entrance aluminum door with good quality glass ranges from 20 to 30 thousand rubles.

When buying an entrance aluminum door, you should not save money, a high-quality construction costs an average of 25 thousand rubles

It is recommended to purchase the entrance group from a warm type of aluminum profile.Using the cold type has many disadvantages. In winter, such doors will freeze through, which will lead to the formation of condensation on the inner surface of the structure. The quality of the seal is another point to pay attention to. Cracks appear on poor quality seals rather quickly - after only one year of using the door.

Internal aluminum doors: characteristics and tips for choosing

Internal structures made of aluminum are used to delimit areas of activity. The operational scope of such canvases is wide enough. They are installed in offices as well as in residential premises. The main difference between such doors and entrance doors is their thickness, which varies from 40 to 48 mm.

When choosing an interior sheet, it is recommended to take into account the quality of the fittings. Components for aluminum doors are selected when placing an order. Most often, the installation of the interior structure is carried out in plasterboard boxes. If the door is installed in an office, then a plastic or glass partition can serve as a frame for it.

A cold profile is used to assemble the doors. From a constructive point of view, there are three types of internal canvases: deaf, glazed, partially glazed. Aluminum structures differ from iron doors with glass in that they have less weight and are cheaper. Thus, an aluminum sheet is a good option at an affordable price. Best of all, such products look in apartments decorated in a minimalist style.

According to the type of opening, all interior structures are divided into two groups: swing and sliding (sliding). The second option is recommended when there is a need to save usable floor space. According to the number of leaves, two types of internal doors are distinguished: single-leaf and double-leaf.

Aluminum profile doors: the most common colors

Manufacturers produce products from an aluminum profile of any color. Thus, everyone can choose a design, focusing on the individual characteristics of the interior and their own taste. Interior doors made of aluminum are very popular in the modern market. The classic option is neutral white.

Note! In addition to the variety of shades, the consumer can choose a door with a glossy or matte finish.

Metal doors with brown glass look presentable in the interior. When choosing an aluminum structure, it is recommended to adhere to one important rule: the hardware must have the same color as the door.

The production of aluminum profile canvases takes into account the use of powder paint materials. There is a special scale, which indicates the variety of colors (and their shades) used in the manufacture of such doors:

- gray (37 shades);

- brown;

- yellow (30 tones);

- orange (13 shades);

- red (24 tones);

- Violet;

- green;

- blue.

In addition, a special neutral group is popular, which includes white, black and metallic colors. Products that are included in this group have a more affordable cost, since the demand for them is consistently high.

DIY aluminum door installation: opening preparation

The order of installation work depends on two factors: the type of door and the type of suspension. As a rule, a corresponding instruction is attached to the kit with the door. Experts recommend focusing on it during installation. Consider the sequence of actions when preparing an opening for a future door.

The first step in the installation work is to prepare the doorway. Much depends on its state, for example, the fact how smoothly the door will be fixed. Insufficiently even edges of the opening affect the strength of the door fastening. Preparation for the installation of an aluminum door includes several stages:

- dismantling of the old structure;

- cleaning from polyurethane foam and other contaminants;

- leveling the opening with plaster;

- opening priming.

It should be noted that leveling the doorway using plaster is the most effective solution. After this stage of work, it is necessary to apply a layer of primer on the edge of the opening. This will increase the strength of the new coating. It is important to remember that during work it is necessary to apply a building level that will allow you to achieve maximum accuracy.

Aluminum door installation: door frame installation

After preparing the opening, you can proceed to the next stage - the installation of the door frame. This operation includes several stages. First of all, it is required to pre-fix the opening. For this, wooden mounting wedges are used. The threshold must be set in the horizontal plane, and the racks in the vertical. The frame needs to be aligned, focusing on the end of the wall. This work requires care and is carried out using a building level.

Helpful information! The error during preliminary fixation of the frame should not exceed 1 mm per one linear meter of the structure.

Next, you need to make holes in the sidewalls into which the anchors will be installed. In this case, it is recommended to focus on the standards for the installation of aluminum doors. Installing anchors is quite simple. Their diameter in accordance with the normative documentation should be 10 mm. The hole is made 1 mm larger. The distance (step) between the anchors should not be less than 0.7 m.

Based on this data, a simple calculation can be performed, as a result of which the number of anchors that will be needed in a particular case will be calculated. For standard doors with a height of 2 m, it is necessary to prepare 3 holes with a diameter of 11 mm on each side. In turn, 2 holes are made in the parallel edges (threshold and crossbar).

The next step is to fix the door frame to the anchors. Before you start fixing the box, you need to remove it and make holes in the wall. They must match the drilling locations in the box itself.

Procedure for the installation of an aluminum sheet

After installing the frame, it remains to carry out the last stage, which involves the installation of the door leaf. Aluminum doors are quite heavy, so the help of another person will be needed for this work. Installing the sash alone can damage the door.

It is important to remember that the hinges must be joined at an angle of 90 °. Door installation performed in the open position. Upon completion of the work, it is necessary to check the operability of all fittings: hinges, handles, and also the lock.

How to determine the correct installation of hinges for an aluminum door? If no mistakes were made during the installation, the gap will be the same along the entire perimeter of the web. In addition, you can make sure that the installation is correct by the movement of the sash: it should open evenly.

After installing the door, it is necessary to check the operation of the components. The lock should close smoothly and silently. It is required that the structure does not have any gaps in the closed position. The height at which the doorknob is located can vary.As a rule, the distance from the floor to this element is 90-110 cm. When opening, the handle should not emit extraneous sounds.

If the hinges are installed correctly, then the gap will be the same along the entire perimeter of the door.

Further, after installing the lock for the aluminum door and handle, it is necessary to fill the empty space between the frame and the wall with foam. It is very important to observe the following rule: filling with polyurethane foam is done from the bottom up. At the final stage, you need to remove (using a construction knife) excess foam protruding from the frame, and carry out a cosmetic finish on these places.

Note! Polyurethane foam usually takes at least 12 hours to dry.

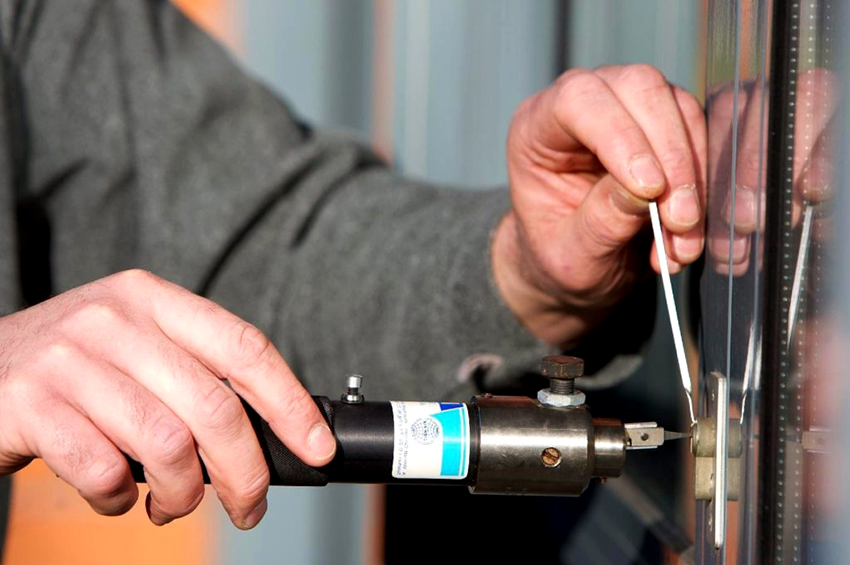

Aluminum door repair and adjustment: tips

Many people are interested in the question of how to independently repair an aluminum door structure that is out of order. First you need to determine the cause of the breakdown. Let us dwell in more detail on the problems that most often arise during the operation of such canvases.

Difficulty opening and closing the sash. The reason for this disadvantage is that the canvas sags on the hinges. To eliminate this most common breakdown, you will need to slightly tighten the screws that fix the hinges. In most cases, adjusting an aluminum door will help restore the structure to normal operation.

In order for the door mechanisms to work for a long time and efficiently, they must be cleaned of dirt and lubricated

A fairly common problem is the increase in the gap between the door frame and the sash itself. Most often, this damage occurs due to wear of the sealing elements. It is accompanied by a deterioration in the thermal insulation and soundproofing of the structure. The solution to this issue in this case is to replace the seals.

Extraneous sounds when opening the sash warn that the structure hinges are clogged. Loose hinges can be another possible cause of this problem. If you are faced with this breakdown, you need to clean the hinges or tighten them.

Overview of prices for aluminum doors: interior and exterior

The price of structures made of aluminum profiles can vary greatly depending on their type and model. The cheapest options are cold canvases. The cost of an aluminum door varies from 7 to 20 thousand rubles. A two-leaf model can cost from 15 to 20 thousand rubles.

Separately, it should be said about the designs of the sliding type. The average cost of such interior doors is 20 thousand rubles. The use of a sliding mechanism in the entrance group will cost more. Products of German manufacturers are sold at a price of 30-50 thousand rubles. It is distinguished by its high build quality and long service life.

The constructions related to the warm group have a slightly different structure, which, of course, affects their cost. The price of an aluminum profile door equipped with sealing elements and a threshold is 20-25 thousand rubles. (average). If desired, you can find cheaper products, but their quality is unlikely to meet the needs of the modern buyer.

Interior doors have a thinner door leaf, so their price is lower than the cost of entrance analogs. Prices differ depending on the design, manufacturer, region, as well as design performance of products.

Doors, the design of which takes into account the presence of an aluminum profile, are divided into two groups: entrance and internal. When choosing such canvases, you need to pay attention to three main factors: cost, appearance and technical characteristics. The design of these doors allows for self-assembly, as well as for repair and adjustment of the sash.