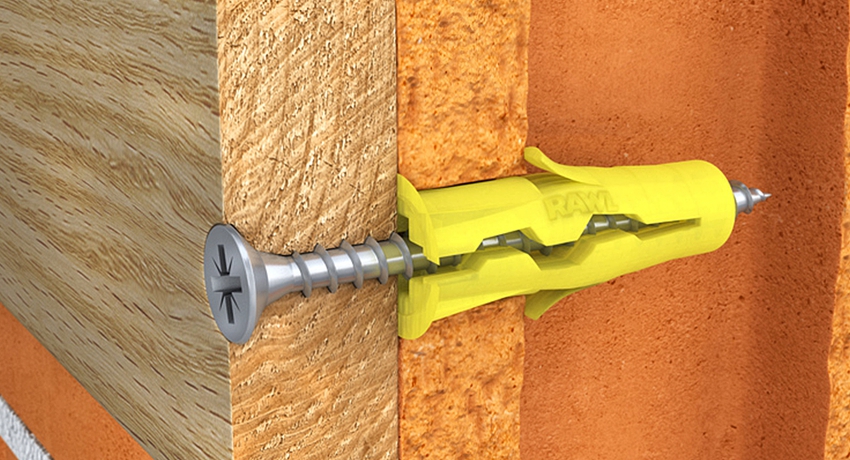

The dowel is the most popular fastener that is used to securely fix any structure or element to a solid surface. The principle of its operation is based on the occurrence of a frictional force, which arises as a result of its expansion in the thickness of the base under the influence of a screw or screw that is screwed into it. The type of fasteners and the type of surface will determine how to install a dowel in the wall.

Content

- 1 Dowel: This is a fastener for fixing a fastener

- 2 Dowel material

- 3 Varieties of fasteners

- 4 How to choose the right dowel

- 5 How to install a dowel in the wall: step by step instructions

- 6 Practical solutions for strengthening the fastening

- 7 How to install a dowel in a wall: mounting technology for drywall

- 8 How can you replace a plastic dowel

Dowel: This is a fastener for fixing a fastener

In order to attach the structure to the base, various fastening options are used. For their reliable adhesion to the surface, various products are used, which include dowels (or dowels).

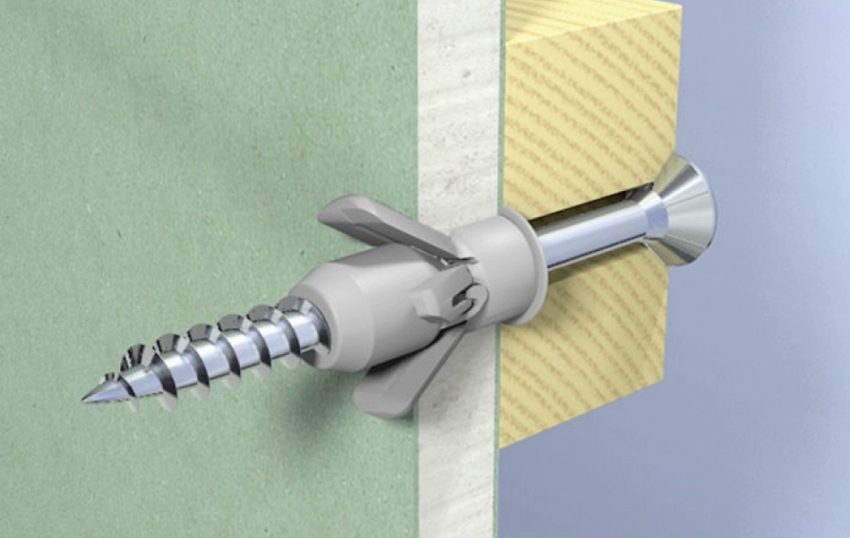

The dowel is a sleeve or sleeve that is inserted into a hole in the wall. The structure consists of two parts: spacer and non-spacer. A screw is screwed into the sleeve, which contributes to the expansion of the spacer part, forming a reliable adhesion of the dowel and the base. The non-spaced part of the product excludes the possibility of turning the screw in the hole.

In the upper part of the dowel for a self-tapping screw, there is a cylindrical, mushroom-shaped or secret type cuff, which prevents the screw from falling into the thickness of the base. The predecessor of the dowel was an ordinary wooden block, which was screwed into the wall, where a nail was subsequently driven in.

Modern dowels are presented in a wide variety of species. They can be used on a variety of surfaces including heavy and porous concrete, brick, natural stone, cinder block, drywall, gypsum. Dowels are produced in lengths of 40-140 mm with a pitch of 20 mm. The inner diameter of the hole is 5-7 mm. The outer section of the product is 6-10 mm. Each product model has a conventional designation consisting of two values: hole diameter and length, which eliminates the need to resolve the issue of how to measure the dowel diameter.

Important! The dowels are selected based on the thickness of the material that needs to be fixed, and are calculated for values of 10-100 mm, since it is important that the product goes into the base to a sufficient depth to open the spacer part.

The main advantages of using dowels:

- reliability;

- easy entry into any surface by impact;

- reliable adhesion of products to the base;

- rigid fixation in any surface, including porous, which excludes the possibility of spontaneous loss of the fastener;

- lack of a torque in slack holes;

- the ability to withstand heavy loads without changing the initial position;

- durability.

Dowel material

Most of the dowels are made of polymeric materials - polyethylene, polypropylene and polyamide. Such elements are characterized by high performance, availability, ease of installation (no need to put significant efforts to fix them) and low cost.

Products made of polypropylene are characterized by hardness, wear resistance, high temperature resistance. Such elements are intended exclusively for indoor installation, which is due to their susceptibility to subzero temperatures. In the course of long-term operation with temperature fluctuations, deformation of the dowels and the appearance of cracks can be observed.

Polyethylene dowels are characterized by light weight, ductility, ability to operate at low temperatures and low cost.

The most reliable and durable products are polyamide or nylon dowels. They are characterized by high wear resistance, resistance to mechanical stress, temperature extremes.

Dowels can also be made of metal. For this, stainless steel, galvanized, bronze or brass-based alloys are used. Iron dowels are distinguished by high strength properties, rigidity, the ability to withstand large mechanical loads and durability without violating the integrity of the structure.

Important! The surface of the metal dowels has a special galvanized coating that prevents corrosion.

Varieties of fasteners

A wide range of dowels is available in hardware stores. Photos of products clearly demonstrate the variety of their designs, materials of manufacture and purpose.

The most common product is the universal polypropylene dowel. It has a traditional design in the form of a sleeve, into the cavity of which a self-tapping screw is screwed. This element is suitable for concrete, brick and stone foundations. The design of the product is equipped with special spacers, with the help of which the element is securely fixed in the hole.

For complex outdoor work, a construction expansion dowel with a stopper flange is used, which eliminates the possibility of fasteners falling into the hole.

Nylon plugs are equipped with fastening tabs, thanks to which the products are securely fixed in the holes. They can be used on all surfaces.

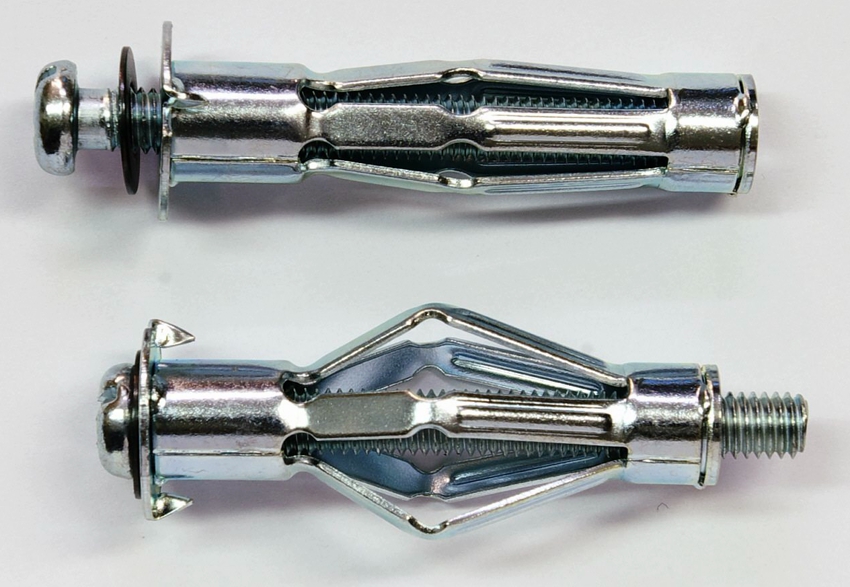

Drywall dowels are used for mounting them in porous concrete and sheets of gypsum fiber and drywall. They can be made of plastic or metal. The last option is called molly dowel. Before hammering in a dowel of this type, it is not necessary to prepare the hole first, since its tip looks like a sharpened drill.

Facade dowels are made of polypropylene or nylon. They have directional tendrils for a secure fit at the base. These fasteners can be used on any surface. They are produced without sides, which excludes the possibility of shedding or cracking of the facing plaster.

The frame dowel is intended for the installation of door and window frames, cladding through layers of thermal insulation and plaster. Products are made of metal.They are often referred to as insulation dowels, which can be of two types: for working with hard and soft materials.

Dowel types with special designs

Dowel nails are made of polypropylene, nylon or stainless steel. Due to the presence of knurling in the form of reverse cones, the product is securely held in the base. They are widely used for quick and volumetric installation of skirting boards, battens, windows, beams, metal profiles, cable ducts, plywood to concrete, brick or stone surfaces.

Useful advice! When deciding whether to hammer or tighten the dowel-nail, preference is given to the first installation option.

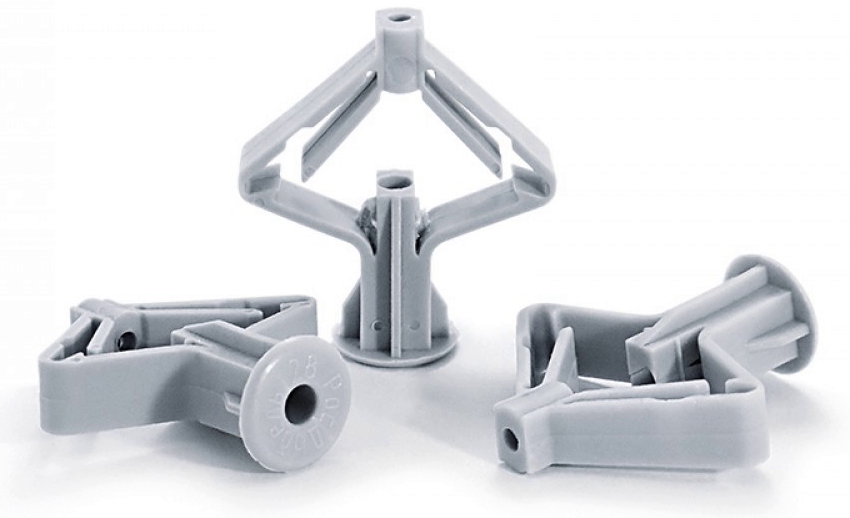

The butterfly dowel is characterized by increased wear resistance, the ability to withstand high loads even in hollow surfaces. Such products are made of metal.

An adjusting dowel is used to mount the battens under the sheathing. It has a special design containing a certain element that allows you to adjust the position of the product relative to the surface to which it is attached.

Useful advice! For the implementation of large volumes of installation work, it is advisable to use dowels-screws designed for assembly guns.

The dowel-clamp has the form of a loop with characteristic antennae for fastening along the edges of the product. Such elements are designed for mounting electrical wiring to the base. The wire is inserted into the clamp, and its edges, in turn, are inserted into the holes previously created in the wall and fixed with tendrils.

A special type of fastening element is an umbrella dowel, which is intended for the installation of polystyrene or mineral wool insulation. Such a product has a wide round cap that holds the insulation. They produce plastic and metal dowels.

Useful advice! The best option for loose substrates would be liquid dowels, or chemical anchors, which provide a strong and reliable connection and at the same time are able to withstand heavy loads.

The Molly umbrella dowel is represented by a nail with metal shoulders, which ensure reliable fastening of structures to hollow surfaces with an even load distribution.

Useful advice! To attach the chandelier to the false ceiling, use Molly's umbrella plugs.

How to choose the right dowel

Dowels for self-tapping screws are selected based on the place of their attachment and the weight of the structure. It is important that the fastener fits snugly into the hole, so it must match the outside diameter. The product is selected based on the base material, which will provide a reliable and durable fixation. You can choose any product to carry out installation work indoors. For fastening external structures, it is better to give preference to elements made of polyamide, which are resistant to temperature fluctuations and low temperatures.

An important point is the type of surface. To deepen the dowel in a solid base, spacers are used. For hollow, layered or hollow-core walls, anchor dowels are used.

Important! There are special dowels designed for a specific type of surface, such as drywall, concrete, sheet bases or facades.

The depth and type of the dowel depend on the value of the load that the fastener will accept. The larger it is, the more powerful and longer the product should be.

For heavy massive products in the form of wall bars or mounted simulators, fasteners with a depth of at least 85 mm should be used.Thinking about how to fix the shelf on the wall, you should take care of purchasing dowels with an outer diameter of 7-11 mm and a depth of at least 30 mm, which will ensure the strength and reliability of the fastening of the structure. In the case of installing ceiling lamps, fixing a suspended ceiling and other products in which the main load is located from the bottom, dowels with spacer antennae or transverse notches are selected.

How to install a dowel in the wall: step by step instructions

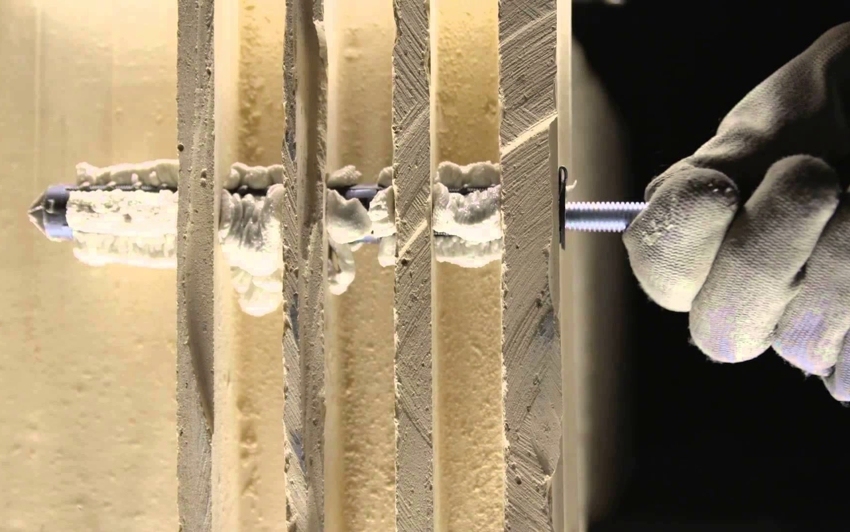

Before installing the dowel in a concrete wall, you should prepare the necessary materials and tools. Fasteners are chosen depending on the type of base. To do this, you will need dowels with screws or self-tapping screws, a hammer, an electric drill, a victorious drill.

Related article:

How to choose a screwdriver to become a real house helper

The main types of devices for their intended purpose and methods of use. What characteristics are considered decisive when buying a product. Manufacturers.

The first step is to outline a place for the hole, which is drilled with a drill. It should be held strictly perpendicular to the base. Using an improvised method, the cavity of the hole is cleaned from cement chips and dust. To do this, you can use a vacuum cleaner. The diameter of the hole must match the cross-section of the dowel, which must fit into it with some effort. If the hole is too large, the fastener will fall out of the hole.

Important! The length of the dowel should correspond to the size of the self-tapping screw that is paired with it.

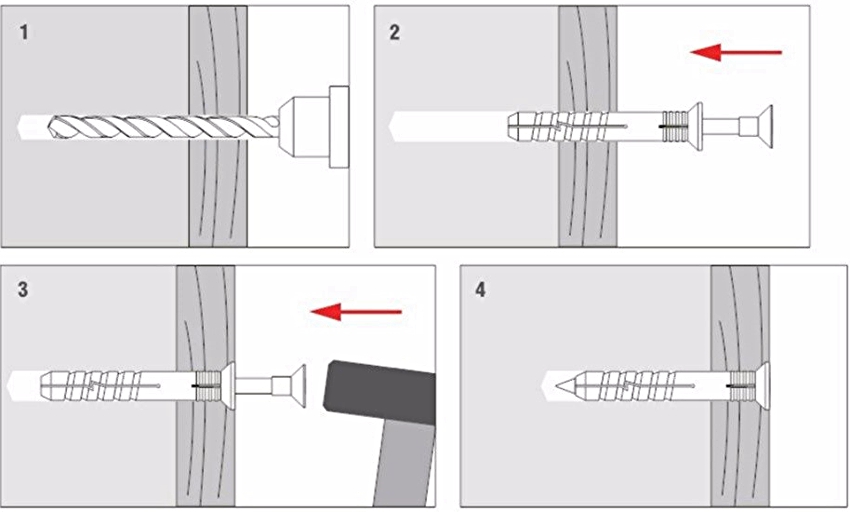

The dowel is inserted into the hole and hammered into it with a hammer until it stops so that the edge of the part coincides with the wall surface. The process is carried out neatly, without powerful impacts that could damage the fastener. A screw is screwed into the dowel cavity. If a nail is used, it will be driven into the cavity of the fastener.

Step-by-step algorithm for installing the dowel: 1 - drilling a hole, 2 - mounting the dowel inside the hole, 3 - driving in a self-tapping screw, 4 - surface finishing

When deciding how to properly install a dowel for aerated concrete, the following recommendation should be adopted. Self-tapping screws for fasteners must be selected with a larger diameter. This will contribute to a significant expansion of the walls of the dowel, providing a rigid and reliable fastening. When drilling aerated concrete or foam concrete with a perforator, the hammer mode is not used, since the hole may turn out to be too large and have an inaccurate configuration, which will complicate the fixing of the dowel.

Practical solutions for strengthening the fastening

When fixing dowels in a loose base, it is difficult to achieve maximum strength and reliability of the fixing. However, there are effective methods to strengthen the connection. A good option for sealing the connection is ordinary electrical tape, which is wound around the dowel. Some craftsmen use ordinary cellophane for this purpose. However, this option is suitable for bindings that will not have heavy loads.

When installing large and weighty structures, the best option to strengthen the connection will be a plaster bandage, which can be purchased at the pharmacy. It is wound on a dowel, moistened, after which the mount is inserted into the hole. After the plaster has completely solidified, a reliable and durable fastening will be provided. If the hole is larger than the diameter of the dowel, you can use a wooden cork or plank to seal it at the base, which is dissolved into thin strips. They are inserted into the hole into which the dowel is driven.

Useful advice! Matches can be inserted into the plastic element, which are used for better wedging of the product due to the tight interaction of the dowel and the self-tapping screw.

An effective but costly method is the use of liquid nails. The glue composition fills the cavity of the hole into which the dowel is inserted. The self-tapping screw is slightly profitable, but does not screw in to the end. This option is best suited for solving the question of how to attach the curtain, since it provides secure fastening for weighty elements.

How to install a dowel in a wall: mounting technology for drywall

The surface of the walls is often sheathed with plasterboard sheets. However, it is not always possible to mount decorative elements or other structures to such a base. This is due to the fragility of the surface and its inability to withstand significant loads. Fasteners for concrete, brick and stone are not suitable for drywall, asbestos, MDF, fibreboard and particle boards. For them, there are special dowels, in which there is mostly no spacer. As a replacement, a double-sided crimp is used for the carrier sheet. The spacer is present only in Driva dowels.

When deciding how to install the dowel in drywall, you should use the technology for installing fasteners on a concrete base, with the exception of some points. Holes for fasteners in drywall should be made using a drill with the impact mode turned off. Their diameter must strictly correspond to the thickness of the dowel, and the length must be 5 mm more than the size of the screws.

In the case of using a self-tapping dowel, at which a kind of drill is located at the end, the element is screwed into the base with a screwdriver or screwdriver. However, if the thickness of the sheets is more than 15 mm, then to facilitate the work, holes must first be made in them.

Before installing the plasterboard butterfly dowel, a through hole is made in the surface. A fastener is inserted into it, which opens on the back side in free space and abuts against the base when the self-tapping screw is screwed into it.

Important! The self-tapping screw for the butterfly dowel must have a length of at least 55 mm, this will ensure full disclosure of the fastening element during installation.

The umbrella dowel is inserted into a pre-prepared hole and opens up in the empty space after screwing in the self-tapping screw. Such a product is supplemented with a fastening hook or ring, due to which it is often used when installing chandeliers.

How can you replace a plastic dowel

For installation work, the most popular fasteners are plastic dowels for self-tapping screws, which can be purchased at any hardware store. However, a situation may occur when they may not be at hand at the right time. In this case, you will have to decide how you can replace the plastic dowels.

The simplest solution is to use wooden chops, which were previously in great demand among craftsmen. These dowels are suitable for all surfaces. Products can be made with your own hands in any quantity. In order for the wooden fastener to be reliable and withstand significant loads, it is important to choose the right material for its manufacture and achieve the accuracy of the product configuration. For a wooden chop, dense and durable types of wood are suitable. The most popular option is pine. Products are made slightly larger than the diameter of the holes for them, which ensures a tight and reliable fastening.

Important! For the manufacture of wooden dowels, do not use loose and rotten wood.

A wooden dowel, previously greased with PVA glue, is hammered into the prepared hole with a hammer.If the product is longer than the depth of the hole, the dowel should be cut with a sharp knife flush with the surface. A self-tapping screw is screwed into the finished wooden chop or a nail is hammered.

Today, dowels are essential elements for creating reliable, strong and durable fasteners. Products are presented in a wide variety of types, and are selected based on the type of surface and the mass of the structure, which will be attached with their help. The process of installing elements is quite simple, but it requires certain rules to be followed.