During construction or renovation work often has to be done at a height. It will be inconvenient to produce them using a ladder. For these purposes, you can assemble scaffolding with your own hands. There are different design options, which are selected based on the nature and complexity of the work. Which type of product is better to choose, how to assemble it or make it yourself, you can read in this article.

Content

- 1 Scaffolding Scaffolding: Design and Product Requirements

- 2 What material is scaffolding made of: product photos

- 3 Demountable frame scaffolding: product price

- 4 Clamp scaffolding: design features

- 5 Wedge mobile scaffolding

- 6 Pin Type Collapsible Metal Scaffolding

- 7 DIY wooden scaffolding

- 8 Attachable scaffolds and construction gantries

Scaffolding Scaffolding: Design and Product Requirements

Scaffolding is widely used in repair and construction. This is an indispensable attribute when performing interior and exterior finishing works at a certain height. The size and design of the scaffolding depends on the nature and complexity of the installation. The main purpose of this building element is to create a comfortable and safe working environment. This increases work efficiency and saves time and effort.

Regardless of the type of construction, scaffolding must be reliable and durable, taking into account the location of people, materials and tools on them. The product should be placed on a prepared, firm and level area. The structure should be located no more than 150 mm from the wall for outdoor use and no more than 100 mm for indoor use.

Useful advice! In the case of using the structure for a long time, it is necessary to provide ditches for draining rainwater from the site so that the soil does not wash out from under the racks of the device.

Scaffolding consists of the following elements:

- racks;

- diagonal and horizontal struts, which impart spatial strength to the structure;

- lintels for flooring;

- stops designed to ensure the stability of the structure and prevent it from falling;

- plank flooring where a person will stand;

- a protective element to protect the employee from falling down;

- stepladders or ladders to climb to the required level.

The width of the deck must be at least 1.5 m.The height between the tiers should be at least 1.8 m. Between the boards and the boards, slots no more than 10 mm wide are allowed. If a continuous flooring is created, the boards can be overlapped along the length by beveling the ends of the elements.

Useful advice! When performing outdoor repair and construction work, it is recommended to use a facade scaffolding mesh, which will prevent workers, materials and tools from falling. It will also provide protection from the sun, dust, wind gusts and precipitation.

Depending on the composition of functional elements and the option of their fastening, all scaffolding is divided into four types: wedge, clamp, frame and pin. Structures are attached, rack-mountable and collapsible. The exception is scaffolding, where frames are used instead of vertical posts. There are also suspension devices that can be installed not only on the ground, but also attached to the building. These include clamp, cup and wedge scaffolding.

What material is scaffolding made of: product photos

Scaffolding - the photos clearly show different options - can be wooden, galvanized, steel and aluminum. The last option is the lightest and most mobile, it is advisable to use it for indoor or outdoor work at a low height. The strongest and most durable are steel structures that are easy to repair, which cannot be said about aluminum scaffolding. Galvanized products are also durable. Their main advantage is resistance to corrosion, so this is the best option for outdoor work, where they can stand for a long time under adverse weather conditions.

The price of scaffolding made of steel and galvanized will be much higher than that of analogues made of other materials. Moreover, such structures are the most heavy, which complicates their transportation. However, such forests are able to withstand not only people, but also the necessary tools and materials. Therefore, steel and galvanized structures are used most often for large-scale construction and installation work.

Today, metal structures from the Dmitrovsky Scaffolding Plant are very popular. The products are characterized by high strength, reliability, durability and reasonable cost.

In addition to metal scaffolding, wooden products are often used, which are simple and economical in execution. They can be easily made independently from scrap materials. However, this design is more cumbersome. Despite the fact that it is collapsible, like other analogues, the boards, due to the fact that they will be stained and damaged by nails, can hardly be used for other events. Such a product is designed to perform work at the maximum level of the second floor.

Demountable frame scaffolding: product price

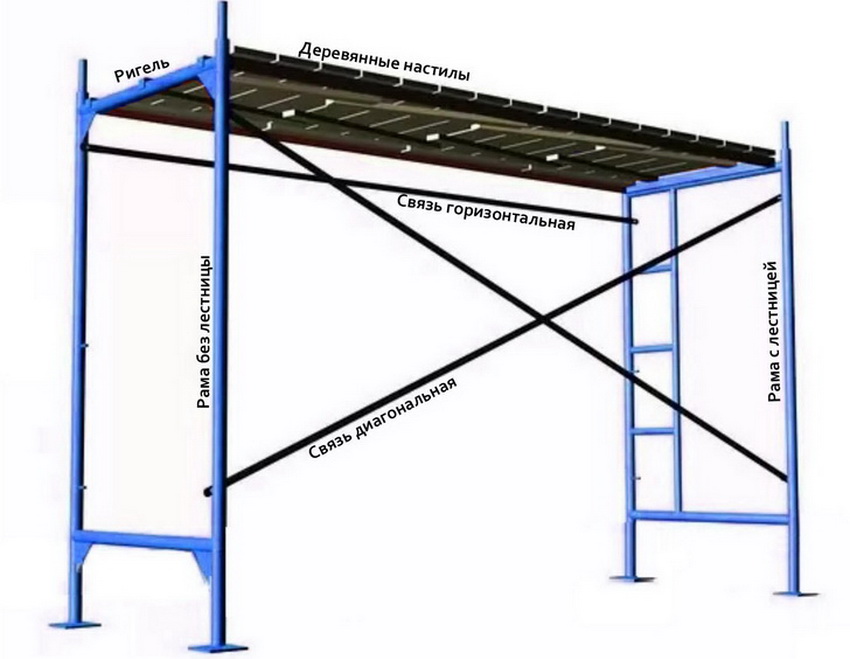

Frame-type scaffolding is the cheapest and easiest option to operate. The structure includes ready-made elements from welded hollow pipes in the form of vertical frames, supports, horizontal and diagonal ties. Due to the fact that a lot of metal is not spent on the manufacture of elements, the structure is characterized by light weight, quick installation and disassembly.

The assembly of frame scaffolding is carried out using flag fasteners or clamps. Such structures are used both for interior decoration of premises and for external plastering and painting works of buildings with a simple facade. Due to its low weight, in the scaffolding, you can easily change the sectioning, as well as transfer them to another place.

You can buy frame scaffolding of one of the types: LRSP-30, LRSP-40, LRSP-60 and LRSP-100, where the numerical value indicates the maximum installation height. However, the structures differ not only in size, but also in the diameter of the pipes and the thickness of the walls of the constituent elements. The first two types are produced with a diameter of 42 mm and a thickness of 1.5 mm, and the other two are 48 and 3 mm, respectively. The price of frame scaffolding starts at 125 rubles / m².

The structures can be equipped with wheels, which facilitates easy movement of the unit on flat ground. The standard dimensions of the product are as follows: section height - 2 m, length - 2-3 m, passage width - 1 m. For one-time work, you can rent frame scaffolding, the price will be 55 rubles / m².

Installation of scaffolding scaffolding: sequence of actions

Shoes and wooden spacers are installed on a prepared, tamped, level platform. The screw supports can be positioned if required. Adjacent frames of the first tier are placed in the shoes with their subsequent connection by diagonal and horizontal ties. In three-meter increments, the next two frames with ties are placed. The process is carried out until the creation of frame lightweight scaffolding of the required length. On the edges of the structure, railing frames are mounted with the subsequent installation of the stairs.

Important! Support surfaces must be located strictly in a horizontal plane.

Next, they proceed to the installation of the second tier, which is also connected by ties, however, the diagonal elements are staggered relative to the previous row. Here you can use the crossbars on which wood floorings are laid. To move people between the tiers, inclined stairs are installed in the places reserved for hatches.

Frame scaffolding attached to the wall in a staggered manner in 4 m increments using hooks with sleeves or plugs with clamps or brackets attached to the uprights of the scaffolding frames. The above steps are carried out until the required installation height is reached.

On the safety and working tier there are longitudinal and end connections of the fences, which are mounted in the place where there are no diagonal ties. Forests are installed along a plumb line. Dismantling of the collapsible scaffolding is carried out in the reverse order, starting from the top row.

Mobile scaffolding on wheels

The most profitable option for quick repairs is the tour scaffolding, which is considered a type of frame installation. The design is robust and easy to assemble. The mobility of the installation is provided by wheels located at the base of the vertical supports. A significant advantage of the tour tower is the presence of a jack in the device design. The height of the product does not exceed 20 m. The loading capacity of the installation is 300 kg / m².

The structure is made mainly of aluminum, which makes it light and easy to move. Less commonly, you can find steel tours with high strength and reliability, but characterized by reduced mobility due to their high weight.

Tower-tours are actively used in the installation of air conditioners, lighting, video surveillance, banners, bigboards, cornices, wall and balcony decoration, gutter and roof repair. There are two types of construction: non-collapsible telescopic and collapsible. In the first version, a special mechanism is provided, thanks to which the tour is extended to the required height. This type is used indoors.

For outdoor finishing or repair work, demountable towers are used, which have a more complex design with supports and diagonal ties.Each subsequent section is built into the supports of the lower module on the bushings, resulting in an overall design. With an installation height of 1.3 m, the structure is completed with handrails and sides. Today you can rent a tower or buy scaffolding, the price of which is in the range of 150-200 rubles / m².

Mobile scaffolding on wheels should be used in cases where it is necessary to frequently change the installation location. Special brake screws are used to fix the structure in place.

Clamp scaffolding: design features

This type of scaffolding is the most laborious to assemble, since each connection of vertical supports with horizontal, diagonal and transverse ties is carried out using special clamps, which are tightened with a wrench. Fasteners can be blind or rotatable. Depending on this, the connection of the racks can be made at a right or any angle, respectively. Due to the fact that a large number of fasteners are required for the installation of a structure, clamp scaffolds are the most expensive.

Useful advice! When assembling the structure, you can combine clamps, which will create the installation of the desired configuration.

Due to the presence of diagonal ties, the structure is strong, reliable and stable. However, this is the most difficult option for scaffolding to install and disassemble.

The main advantages of the design are the ability to manufacture an installation of any shape and the expediency of combining it with another version of the auxiliary rack-mount metal structure. Such a structure is mounted around the perimeter of a building of any configuration, even with protruding elements. The device can be used for inclined structures.

Related article:

Insulation of a wooden house outside: the choice of material and technology

What materials are used to insulate a wooden house. Do I need to insulate the foundation. The best modern technologies for insulating wooden houses.

Manufacturers produce various options for scaffolding of the clamp type, differing in the maximum installation height, which can be from 30 to 80 m.The standard width of the scaffolding is 1-1.5 m, the step of the tier is 2-2.5 m. These parameters vary depending on configuration of the structure. The maximum load on the structure is 150-250 kg / m. The installation can be bought or rented. The price of scaffolding starts from 250 rubles / m2. Rent will cost 80 rubles. per m2.

Useful advice! Clamp scaffolding is recommended for creating stages and stands.

Wedge mobile scaffolding

This structure is created from functional elements using a special wedge fixation. Flanged pipes are used as vertical components, pipes with holders are used for horizontal components. To make the installation more mobile, it is recommended to equip it with special wheels. Such scaffolds are characterized by strength and reliability. When installing the unit, you can change the direction angle of the connecting elements, thereby creating multi-level structures of various configurations.

Manufacturers produce wedge scaffolding in the following sizes: section height - 2 m, length - 2-3 m, passage width - 1-3 m. The structure can have heights of 60 and 100 m. used during the construction of complex objects in the case when lifting heavy units and materials.

Useful advice! To ensure the safety of people who may be near the construction site, it is recommended to buy a scaffolding net designed to enclose the facade of the building.

The scaffolds are easy to use, but require laborious installation. The design is characterized by its versatility, thanks to which it can be used not only in the construction of buildings, but also in the construction of stages, stands, sheds, overpasses. It is an irreplaceable installation in ship and aircraft construction. The cost of the construction starts from 425 rubles / m². You can rent scaffolding for 85 rubles / m².

Pin Type Collapsible Metal Scaffolding

Such designs are very popular on construction sites due to the easy and quick installation and disassembly of the unit. As a connection point in the scaffolding, pins are used, which are located on the bearing supports. They fit into the holes in the connecting element pipes. The installations are characterized by strength, reliability, rigidity, stability, wear resistance and durability. They can be used many times, easily transporting from place to place disassembled.

Due to its high load-bearing capacity, the structure can withstand a significant amount of heavy building materials. Such forests are used in areas with difficult terrain and during construction and installation works of structures of a curved configuration. The design disadvantages include the large weight of the installation, which is associated with a significant amount of metal.

Today, the sale of pin-type scaffolding of the following varieties is carried out:

- LSH-50 - up to 50 m high, sectional 2 m high, 1.5-3 m long, 1-2 m wide;

- ЛСПШ-2000-4 - 40 m high, 1.6 m wide passage, 2 m high sections, 2.5 m long;

- E-507 - 60 m high, 1.6 m wide passage, 2 m long and high sections.

You can buy a structure from 519 rubles / m². Also, some companies offer to rent the installation. The price of a square meter of scaffolding is 90 rubles / square meter.

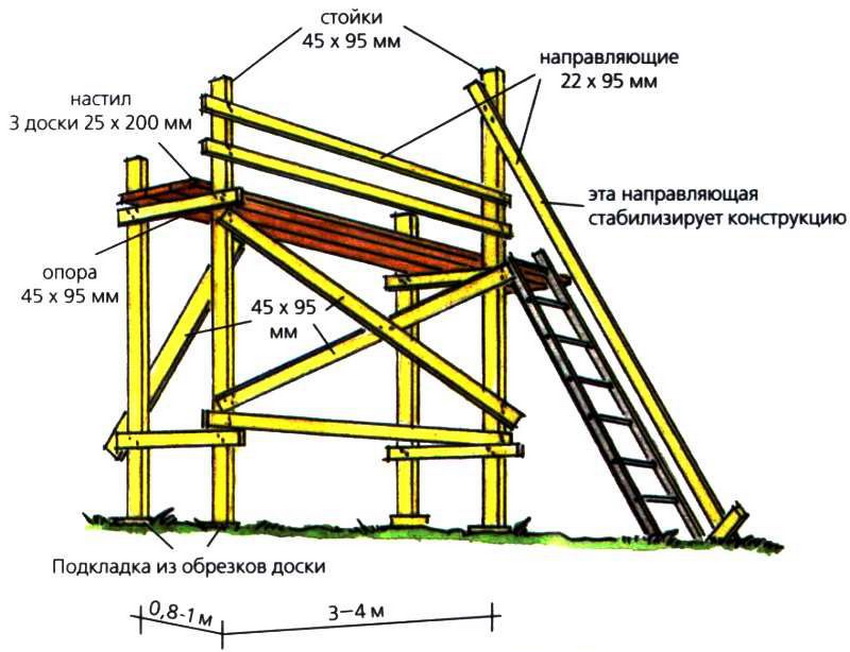

DIY wooden scaffolding

If there is a desire to save money, and materials made of wood are at hand, then you can create a structure yourself. Before making scaffolding with your own hands, you should study the requirements for the product so that it is durable and reliable.

The distance between the vertical posts should not be more than 2.5 m.The installation height reaches 6 m.The width of the flooring can be any, but not less than 1 m.It is important that not only a person can fit on it, but also the tools and materials necessary for work ...

For supports and racks, use wooden beams with a section of 100x100 mm and boards - 50x100 mm. The thickness of the products for the spacers should not be less than 30 mm, and the thickness of the flooring - 50 mm. For stiffening ribs, you will need products 25 mm thick. Thin boards can be used as enclosing elements. To create a reliable structure, it is necessary to use exclusively construction nails. Self-tapping screws are not able to create a reliable connection.

Useful advice! When installing wooden scaffolding, you should take care of their convenient disassembly. For this, it is not recommended to hammer in the nails completely, and you can also use a wooden spacer between the element of the structure and the head.

After the complete set of the installation is prepared, they start assembling it. The work starts with large functional elements. Two beams are laid on a horizontal surface at a distance of the length of the structure so that the tops of the elements converge slightly, which will add stability to the installation. For example, if the distance between the lower ends is 3 m, then there should be no more than 2.6 m between the upper ends. Sidewalls are attached to the inner side of the supports, which are the basis for the decks.A similar operation is done with the other two bars.

Useful advice! The lateral cross members must have different lengths to result in a pyramidal structure.

The sides are vertical and tilted towards each other for stability. The position is fixed with long transverse nails. To prevent the scaffolding from falling on the wall of the structure, it is recommended to make the cross-members with an allowance of 20-30 cm.

The racks are installed at a distance of 2-2.5 m, depending on the thickness of the boards used for the flooring. The elements are attached to each other using slopes, thanks to which the structure does not fold to the side. The more jibs and crossbars, the stronger and more reliable the scaffolding is made by hand. If the height of the structure is more than 3 m, it must be additionally secured so that it does not fall forward. For this, jibs are installed, which, on the one hand, are nailed to the beams, and on the other, they are buried in the ground.

The final stage is the installation of the flooring to the transverse beams. It is also possible to additionally install fences over each platform to increase safety. If you add crossbars to the side elements, a staircase is formed. To give the structure stability, the ends of the supports should be sharpened and buried in the ground.

Attachable scaffolds and construction gantries

Attachable scaffolds are used for simple finishing works where lightweight materials are used. Wooden structures lean against the surface of the building wall and are held by a stop. Although the unit looks unreliable, it is convenient and safe to operate. There are two options for the execution of the attached scaffold: traditional and Armenian. The first installation is simple and reliable, however it is not height adjustable. It can be used for filing roof overhangs, installing gutters and other works that are characterized by a small variation in height.

Armenian forests are produced from the minimum amount of materials, easily and quickly assembled, moved and disassembled. The main thing is to make triangles, raise them to a given height, place them in 3 m increments and support them with inclined beams that are fixed in the ground.

For exterior finishing of one-story buildings and for work on gables, construction racks are used, where the flooring is laid on wooden beams. Installations are also used in cases where nothing can be supported on the walls. The structure is not cumbersome and light, it can be moved to the desired location.

The construction goat is a four-legged wooden structure resembling the shape of the letter "A", the height of which reaches the height of a master. The number of spacers can be arbitrary. Conventional canopies are used to connect the upper ends of the supports. The legs are fixed with stops. On one side, the stand can be made vertically, without inclination. This will allow you to install the structure closer to the wall, which is convenient for painting, caulking or preventive treatment.

Thanks to the variety of scaffolding options, it is possible to select the design required for specific work. When choosing a product, it is important to take into account not only its cost, but also the features of the terrain, the surface to be treated, the timing of the work. Based on this information, it is easy to choose your type of construction for each case.