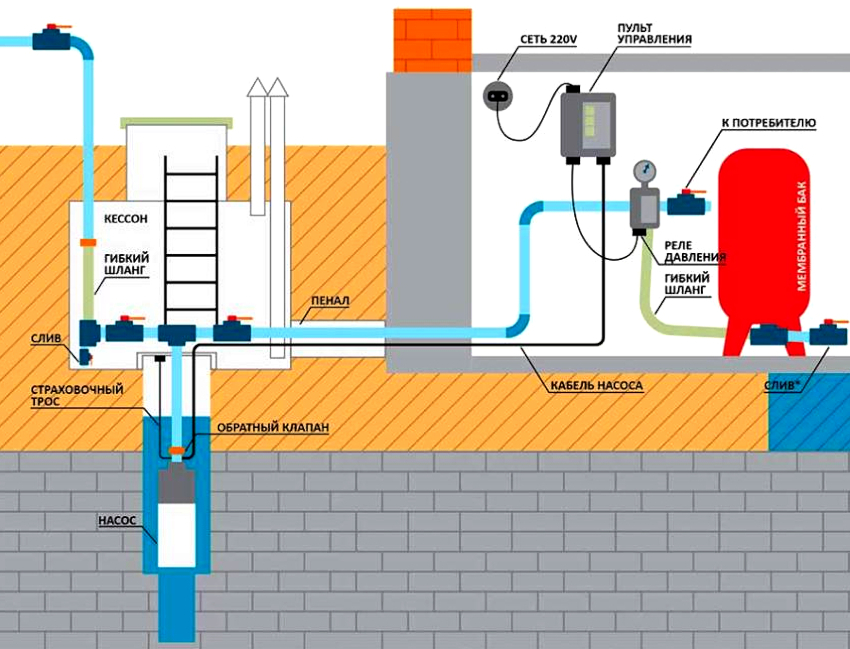

To make the level of comfort of using centralized water supply and the source of a country house in the form of a well or a well identical, there is a special device - automatic equipment for the pump. It will not only provide a stable supply, but also allow you to regulate the water pressure in the system, setting the required one, and also protect the pump from voltage surges.

Automation for the pump not only ensures a stable water supply, but also makes it possible to regulate the pressure in the system

Content

- 1 The main functions of automation units for pumps

- 2 Features of connecting a hydraulic accumulator to a well

- 3 Types of automation for a pump without a hydraulic accumulator

- 4 Automation and connection of the "Malysh" borehole pump

- 5 How to make a water pump with your own hands at home

- 6 Reasons for reducing the pressure in the system and how to increase the water pressure in the pumping station

- 7 Varieties of "Pampel" automation for centrifugal and vibration pumps

- 8 Automation for the pump "Dzhileks": types, functions, compatibility with other devices

- 9 Installation and adjustment rules for "AQUAROBOTA TURBIPRESS"

- 10 Well pump with automation: features of functioning, connection

- 11 How to raise water to a height without a pump: video, description

- 12 Automation for the pump: what to consider when choosing

The main functions of automation units for pumps

A large number of suburban areas are equipped with wells and wells. Owners strive to have an autonomous water source. More often it is a technical resource that is used for irrigation. But also as drinking water such water is used quite actively. In terms of chemical composition, it can significantly exceed tap water, especially if the intake is carried out from a great depth.

The scheme of operation of automation for water supply pumps and wells in terms of efficiency is not inferior to central systems

In order for the process to be technically optimal and meet the requirements, many people prefer to buy automation for a borehole pump. By functionality, mechanisms can be divided into two types:

- automatics regulating water supply;

- protective system.

Regulating mechanisms allow you to adjust the required flow. When watering - more intensive, for domestic needs, including for supplying heating and household appliances - less force.

A protective mechanism prevents damage to the unit in the event of a significant voltage drop. In situations where the water level has changed, pumping is not possible; when turned on, dry running is performed.

A well-established scheme of well operation and automation for water supply pumps is not inferior to central systems in terms of operating efficiency and even surpasses them in some respects. When using an individual source, interruptions and shutdowns are excluded, the cost of electricity is less than payment for the amount of water consumed from the central supply system. In cases where it is possible to use it as a drinking water, the overweight becomes even more significant.

Types of protective automatics for a borehole pump, connecting blocks

When choosing an automation unit for a borehole pump, you should pay attention to the voltage indicator recommended for the normal operation of the latter, and to the permissible deviations. To protect the device from running out of water, a U-shaped relay must be installed. This element will turn off the pump if no water is supplied to it.

Modern manufacturers offer several types of protective mechanisms to ensure the safe operation of pumps:

- start-up protection, they are based on printed circuit boards;

- relay blocks;

- devices, the functioning of which is provided by microprocessors.

The scheme for connecting a borehole pump to an automatic device that prevents overheating is carried out by performing the following steps:

1. You need to prepare the equipment. You need to purchase:

- hydraulic tank (hydraulic accumulator);

- pressure gauge;

- adapter sleeve with collet clamp;

- plastic pipes and brass adapter.

2. Wrap the entrance to the hydroaccumulator with fum-tape, screw on the adapter sleeve.

3. Connect the pressure gauge and relay to the brass adapter.

4. Connect the brass adapter and the adapter sleeve.

5. From a plastic pipe, assemble an elbow that will combine the relay and the battery with the water supply system.

6. Connect the borehole pump hose using a collet-type sleeve.

Important! After assembling the system, be sure to check that the cable is securely attached to the terminal block.

Regulating automation for submersible pump

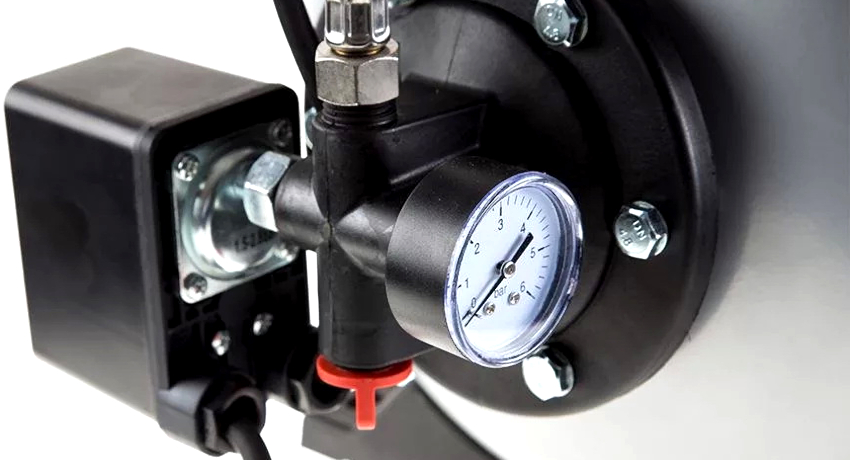

The automation system that regulates the operation of the pump consists of several elements. The main one is the control relay, which is supplemented by the electrical part. Depending on the features of the configuration, two principles of device operation are distinguished.

Regulation of water pressure in the pipeline. It works when water is supplied from a well and the system has a hydraulic tank. After the first ascent, it fills the container, then it is fed into the house system. Automation operating according to this scheme has a sensor with electrodes.

Some units (more often designed for wells) are equipped with special floats to control the amount of water. It should be noted that the price of submersible pumps for wells with this type of automation is quite high, but the devices are in demand. Regardless of the method of controlling the filling of the accumulator, all tanks have an emergency drain, which, if necessary, will reduce the pressure in the tank. A positive characteristic of the work of just such a control system is the stable operation of the pump, provided by constant hydraulics.

Level control. It is carried out using commands. A certain pressure is set on the relay, the pump turns on and off depending on its change. A similar scheme is actively used in private areas, it also assumes the presence of a membrane tank. The relative ease of installation and the low price of automation should be noted as positive characteristics of such a scheme.The ideal picture is slightly spoiled by the inaccuracy of readings and a short service life in a system with vibration pumps.

Important! When using a pressure level control circuit, a relay can be installed in the power circuit of the pump.

Features of connecting a hydraulic accumulator to a well

The article more than once mentioned a hydraulic accumulator (aka a hydraulic tank, a membrane tank). In general, the purpose of this element of the water supply system is clear, but its role is so important that the issue requires more detailed consideration. The principle of operation of the tank is as follows:

- water enters the membrane, free gas is compressed, increasing the pressure on the stretched rubber;

- the tank is full - the relay turns off the pump;

- after opening the valve, the pressure drops, the relay turns on the pump again and brings the pressure indicator to the required value.

The operation of the membrane tank described above directly indicates that the main type of automation for a downhole pump with a hydraulic accumulator is a pressure control switch. The tandem of the diaphragm tank and the relay significantly increases the service life of the pump, since it provides protection against water hammer when starting the pump, and also reduces the frequency of starts - a small amount of water is supplied from the tank.

When connecting a hydraulic accumulator to a well, the installation of a check valve is of great importance. Its main function is to prevent water from going back into the well. The valve is mounted on the pump at its junction with the supply pipe. Mounting method - threaded. The thread is tapped onto the pump cover. The installation of the system has a strict sequence: first, the valve is installed, then the hydraulic accumulator is connected.

Helpful advice! In conditions of unstable replenishment of the water reservoir, it is worth purchasing an automatic device with a water search function (automatic reset) for a pump with a hydraulic accumulator after the dry-running protection is triggered.

Types of automation for a pump without a hydraulic accumulator

It is also possible to organize a high-quality water supply from a well or well without the presence of a membrane tank in the system. The main condition is a high-quality pump, the technical characteristics of which will correspond to the operating conditions of the unit. It is also important to select automation for the deep pump, which will maintain constant water pressure in the system: pressure switch and protection against voltage surges.

The action of water supply without a battery can be described as follows:

- when the tap is opened, the sensors and relays respond to pressure changes and automatically turn on the pump, which supplies water directly from the well or well;

- a closed valve helps to stabilize the pressure, which is fixed by the controlling automation, and the pump is turned off.

With every use of the water supply system, even if a minimum volume of liquid is required, the pump turns on. It is this moment that most of all affects the wear factor - the pump breaks down faster than a unit that has a hydraulic accumulator in the system.

Correctly selected automation is able to organize high-quality water supply even without a hydraulic accumulator

The positive characteristics of water supply without a membrane tank include the following:

- simplicity of the pump connection diagram. The main elements are pump and automation;

- small size of devices;

- affordable price of the system as a whole;

- the ability to supply water under a high (in comparison with a system equipped with a membrane tank) pressure.

The protective and regulating automatic protections of the pump without a hydraulic accumulator will ensure its long-term operation without breakdowns if the system is used at a medium or low intensity level, for example, by a family of 2 people.

Automation and connection of the "Malysh" borehole pump

A special place among the many models of submersible pumps is occupied by "Malysh". Almost all summer residents and residents of country houses who use wells are familiar with him. Even if a more powerful unit was subsequently purchased, the well was pumped by the vibration "Kid".

Before figuring out what kind of automation is needed for the "Kid" pump, it is worth considering its technical characteristics:

- pump capacity - 430 l / min. (without lifting);

- rise to a height of up to 40 m;

- engine power - 250 W.

The water intake can be upper or lower, depending on the model. The upper suction position cools the engine better as it is completely submerged in water during operation. There is also no unnecessary suction of sludge or other unwanted particles from the bottom of the well.

Important! Do not use the Malysh pump to pump out heavily contaminated water. In such a situation, a quick failure of the electric motor is inevitable.

As for the automation for the vibration pump, including for the "Kid", the most standard models are suitable. Most of the Malysh pumps have built-in protection against overheating, which may occur during a voltage drop or dry operation. You only need to purchase a command relay additionally. Regarding the use of a hydraulic accumulator, the situation is as follows: this unit is extremely necessary to maintain the durability of operation. It is worth connecting to the system a membrane tank with a capacity of 25-50 liters, it is this volume that is optimal with the power of the "Kid" pump.

How to make a water pump with your own hands at home

Summer residents are not lazy and smart people. Therefore, the question of how to make a pump for water without electricity with your own hands is often asked. In fact, there are many options, all of them are quite realizable. One of the most effective and most affordable is a pump based on a pump mechanism. It is this one that is often used in the absence of electricity.

To create a pump, you will need the following elements and parts:

- PVC pipe with a diameter of 5 cm;

- PPR pipe with a diameter of 2.4 cm;

- two check valves 0.5 inch each;

- plugs and pipe bends;

- bolts 8 mm with nuts, rubber gaskets.

The pump is assembled from the above parts. The main thing is to ensure the tightness of the structure, otherwise the mechanism will not work. The piston creates pressure in the working chamber. Under its influence, water, passing through the valves, is supplied to the outlet. It is very important that the gaskets fit snugly.

Related article:

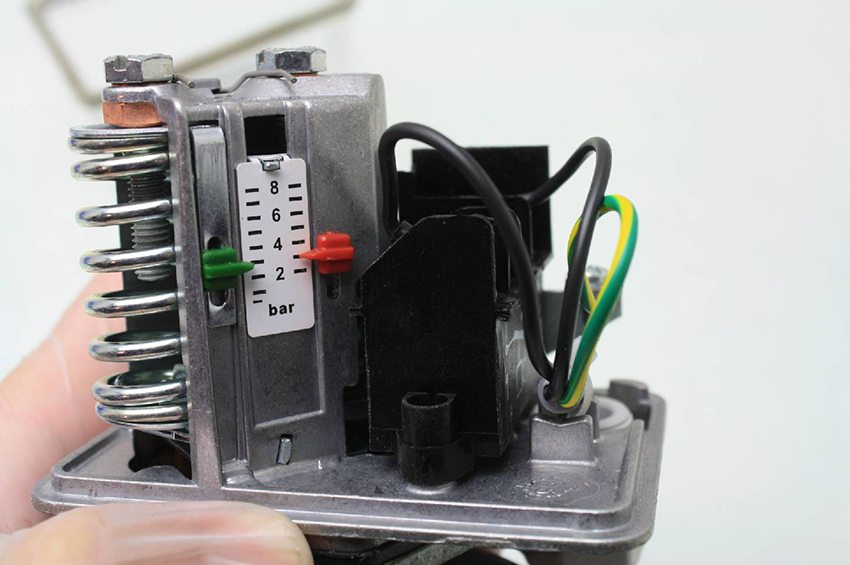

Pressure switch for a hydraulic accumulator: how to install and configure correctly

Purpose and place of installation of the pressure switch. Rules for adjusting and configuring the device.

It is difficult to perceive when describing, but in fact it does not cause problems to create a pump powered by solar energy with your own hands. The principle of operation is somewhat reminiscent of how a submersible pump is connected to a hydraulic accumulator: gas takes part in pushing water out.

Required components:

- metal grill;

- rubber pear;

- a cylinder with a propane-butane mixture.

The grate is filled with gas and connected to the pear. The pear is placed in a tank pre-equipped with inlet and outlet valves. Solar energy expands the gas, the latter pushes air out, providing a pressure drop across the water tank.

Important! All tank seams must be sealed. It is necessary to locate such a pump in a well-lit place.

Reasons for reducing the pressure in the system and how to increase the water pressure in the pumping station

Situations when the water pressure in the pumping station does not meet the requirements are quite frequent. Do not rush to adjust the operation of the water pump automation. To solve problems, first of all, it is worth carrying out the following diagnostics:

The water pressure is influenced not only by automation, but also by the condition of the filters, the air pressure in the system, and the tightness of the suction pipeline

- Check the condition of the filters. Admixtures of sand, clay and other elements can not only clog the filters, but also cause corrosion of system elements, which will certainly affect the efficiency of the pump.

- Measure the air pressure in the system. Its decrease also affects the full functioning of the station.

- Make sure that the suction line is tight.

If, as a result of the above actions, no problems are identified, it is necessary to intervene in the operation of the automation: check the condition of the accumulator and adjust the pressure switch for the borehole pump. Quite often, a mistake is made in which a high level of lower pressure is set. The station practically does not turn off in this mode, which, naturally, has a detrimental effect on its functioning.

The reason for the weak pressure can also be damage to the membrane, microcracks in the tank. Sometimes the elimination of defects is impossible, a complete replacement of the accumulator is required.

Varieties of "Pampel" automation for centrifugal and vibration pumps

Among the automation for borehole pumps, units manufactured by Pampela LLC are especially popular. The company produces two types of devices:

- Designed for vibration pumps. These include "Vistan-3".

- Applied for centrifugal pumps. Here the choice is somewhat wider: "Pampel" KIV-1B3, "Pampel" KIV-1V3, "Pampel" KIV-1A3.

The "Vistan" -3 device can be applied when supplying water from various sources: reservoirs, reservoirs, wells, wells. Compatible with pumps such as "Kid", "Trickle", etc.

The main functions of this type of automation include the following:

- ensuring smooth start and stop of the pump when using a standard starting system;

- turning on the pump when opening the tap, as they say, after receiving a certain command;

- protection against the harmful effects of voltage drops, dry running;

- can be used as a water pressure regulator in the system.

A downhole pump for a well with automatic Pampela will work stably and will last much longer than a device without such protection.

Pump automation "Pampel" KIV (1A3, 1B3, 1V3) monitors, controls and protects the operating device. Provides switching on without water hammer, restarts the system after failures and accidents, protects against voltage surges, as well as when the pump is operating in the absence of water intake.

Helpful advice! The company "Pampela" is engaged in the development, production and sale of pump automation. In order to avoid the acquisition of fakes and, if you wish to avoid trade markups, it is worth buying units in the manufacturer's stores.

Automation for the pump "Dzhileks": types, functions, compatibility with other devices

Automation units for pumps "Dzhileks 9001" have also proven themselves in the domestic market. These are universal devices that are compatible with all models of centrifugal, vibration, vortex and screw pumps. To ensure the most efficient work with pumping devices, it is necessary that the latter have the following technical characteristics:

- had a throughput of up to 100 l / min;

- worked on mains voltage no higher than 230 W;

- the current strength was 6-8 A;

- the pumped water did not exceed a temperature of 75 ° C;

- the pipe had a cross section of 1 inch.

It is very important to install the automation unit correctly. It should be noted that "Dzhileks" devices are powered from an ordinary household power supply. The devices are installed only vertically, the blue cover must be in the upper position. Automation is installed between the consumption point and the pump.

Automation equipment for the "Dzhileks" well can be of different modifications. In particular, the set sometimes lacks measuring instruments. In such cases, the gauge should be purchased additionally and installed on the side panel.

Produces "Dzhileks" and other, simpler types of automation. These include the Crab systems. They maintain the required pressure in the line, if necessary, turn on and off the pump. Their design includes a filter that removes solid impurities from water.

The RDM-5 relay option maintains the required pressure level in the water supply system. The device is simple, compact and inexpensive. It is connected to the pump with an electric cord. If the pressure drops, contact appears, the pump begins to pump water into the system. At normal (user-set) pressure, there is no contact and no water is drawn.

Installation and adjustment rules for "AQUAROBOTA TURBIPRESS"

The AQUAROBOT TURBIPRESS block is designed for automatic control of both surface and submersible pumps. This automation is compatible with single-phase pumping devices, the power of which does not exceed 1.5-2.2 kW.

The main automation functionality is as follows:

- control of the pump by maintaining in the system a user-specified upper and lower pressure;

- shutdown of the pump in the absence of the possibility of water intake;

- maintaining the operating state of the system when the voltage drops to 170 V.

"AQUAROBOT" has the following technical characteristics:

- permissible operating voltage - 170-250 V;

- maximum current - 16-20 A;

- the maximum throughput of the pump is 120 l / min, the minimum is 3 l / min;

- pressure level for switching on - 0.5-4.5 bar, for switching off - 2-5 bar;

- protection response rate - 5.5-7 bar.

The connection diagram of a deep-well pump with "TURBIPRESS" automation is standard: the unit is installed on the pump pressure pipe up to the first point of water consumption from the system.

It is not allowed to connect this automation to the system without a hydraulic accumulator. The minimum volume of the membrane tank must be at least 20 liters.

Important! When using a vertical accumulator in the system, it is impossible to install the "TURBIPRESS" automation on the flange of the diaphragm tank.

Well pump with automation: features of functioning, connection

Is there a difference between borehole and well pumps? Yes, but it will be more accurate to say that pumps with certain technical characteristics are used to pump water out of the well. These are monoblock centrifugal devices, where the engine, water intake elements and a branch pipe are located in one housing.

The well pump is installed at a depth of no more than 25 m. It has a rather low performance. The automatic well pump should be positioned so that it does not drift over the water bed. It is also necessary to exclude vibrations of the unit, as they will raise all kinds of unwanted particles from the bottom.

It should be noted that protection against the ingress and adhesion of solid particles to the impeller blades in well pumps is weak. Therefore, when pumping contaminated water, they quickly lose their rated capacity.

Well pumps, that is, centrifugal pumps, differ from vibration ones and in the way of protection against dry operation.It consists in the following: with a decrease in the intensity of the water flow entering the pump (when air enters), the current of the electric motor of the device also decreases. The sensor reacts to this situation, giving a signal to turn off the unit.

The connection diagram for a submersible pump for a well is almost the same as for a well. The only difference is in the method of fixing: the borehole is attached to the head; for the well, a metal frame is made, a hole is made in it, into which the cable is inserted.

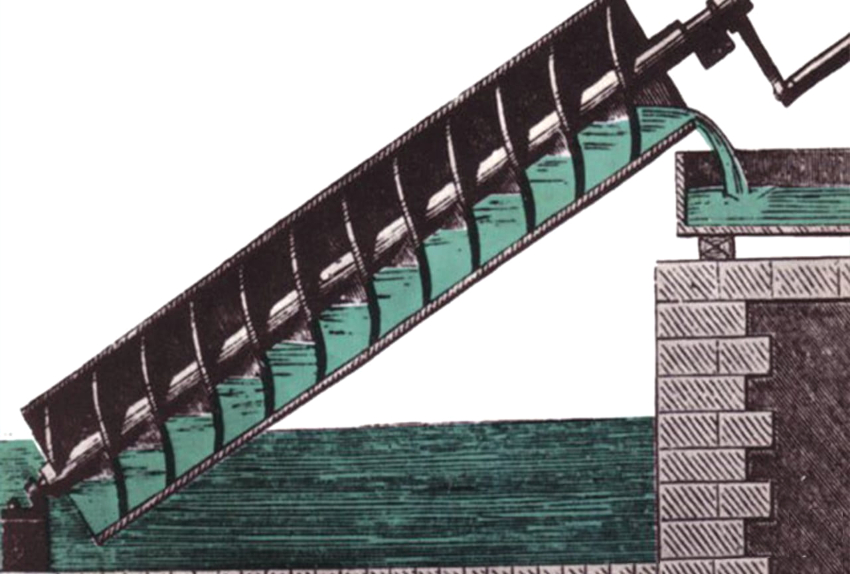

How to raise water to a height without a pump: video, description

Do not rush to assess the conditions of soil cultivation without the availability of electricity as extreme. It is in such situations that a considerable number of gardeners find themselves who have developed land plots in wastelands and other unclaimed territories. Savvy and useful experience, which many share on the Internet, make it possible to organize the supply of water even without electricity.

There are a lot of such pumping methods. The most accessible are the following:

- Application of Archimedean screw. The device consists of a hollow cylinder and a screw placed in it with a handle for rotation. The system must be lowered into the source at an angle. A screw, set in motion by a mechanical means, draws in the water and conveys it up.

- Using a hydraulic ram. The method was invented by the mechanic Montgolfier. It is based on the kinetic energy of water: the flow passing through the rigid pipe is shut off, the water rushes through the check valve into the hydraulic tank located above. The tank is equipped with a fitting at the bottom, on which a hose is put on, supplying water to the consumer.

For more information on how to raise water to a height without a pump, watch the video:

Helpful advice! When creating a mechanical water supply device, it should be borne in mind that the most effective and affordable way is a piston system.

Automation for the pump: what to consider when choosing

When choosing automation for a well with a submersible pump or for a well, two main factors should be taken into account:

- technical condition of the water source;

- functionality, manufacturer and price of automation.

As for the latter, the parity of price and quality is one of the main conditions influencing the choice. You can buy a cheap and small-sized Chinese device, but it should be understood that its life will be limited - 1-2 years under simple operating conditions. Most often, these options require additional purchase and installation of a pressure gauge.

When choosing automation for a pump, you need to pay attention to the technical condition of the water source, functionality and price of the product

More expensive, but at the same time affordable and compact Polish and Italian models are characterized by almost twice the service life in comparison with Chinese versions. They already have a pressure gauge, but most often there is no dry-running protection function.

Expensive multifunctional units are equipped with electronic systems, which provide more accurate control over the operation of the pump. If the pump is with a hydraulic accumulator, then the automation itself will cost less than models for units without hydraulic tanks. It is impossible to find a cheap Chinese version for systems without a hydraulic accumulator.

When choosing automation, it is also important to take into account the condition of the water layer. If the level does not decrease with a significant water intake, then it is not at all necessary to purchase a device with a dry-running protection function.

Water is the source of life. And like everything valuable and important, it requires attention, careful and reasonable attitude.As soon as the source begins to dry out, comfort is lost. Problems are always easier to prevent than to solve, painfully getting rid of the consequences. Correctly selected and installed automation is the key to a stable water supply.