Woodworking requires special skill and much more time and effort than is spent in the manufacture of factory products. But the result is much more expensive, appreciated higher and looks many times better than conveyor factory wooden products. For successful work, the main thing is to choose a suitable multifunctional household woodworking machine: the final result will depend on its quality and compliance with your tasks.

For successful work, the main thing is to choose a suitable woodworking machine, which will have the functions necessary for the master.

Content

- 1 Is it worth buying a universal woodworking machine for the home: the main advantages

- 2 Which multifunctional woodworking machine to buy: device classification

- 3 Prices of woodworking machines for home, depending on the type and capacity of the equipment

- 4 Types of multifunctional household woodworking machines 220 V

- 5 Multifunctional household woodworking machine: scope

- 6 Household machine device. Its functions and the purpose of various tools

- 7 Choosing a household machine: important characteristics

- 8 Advantages of the combined universal woodworking machines D300, D400 and other models

- 9 Comparison of different models of woodworking machines

- 10 Important rules for working on a universal machine

- 11 Multifunctional woodworking machines: video reviews of devices

Is it worth buying a universal woodworking machine for the home: the main advantages

The machine once and for all changes the approach to working with wood. Such devices allow you to create unique wooden objects without spending a lot of effort and time. Woodworking machines can be useful not only in production - large or small, but also in the home workshop.

Among the advantages of woodworking machines are the following:

- low fatigue of the master during work and, as a result, high speed of the process and high productivity. Indeed, with manual labor, much more effort goes away, concentration of attention is lost from fatigue and work goes slower;

- productivity increase. In the same time on the machine, you will do seven times more than by hand, even if you use an electric tool;

- high quality products. Even if you do not have a lot of experience in woodworking, thanks to the machine you will immediately achieve high precision of work. In the case of manual machining, you move the tool over the part.On a desktop woodworking machine for the home, the part itself moves. This gives you a better control over the process as well as a thorough view of the incision area;

- high degree of work safety;

- in case of overheating, a protective shutdown of the equipment is automatically triggered, which significantly extends the service life of the machine;

- ease of setup and operation;

- comfortable work due to low noise level;

- the ability to choose the right model at an affordable price, for example, you can find and buy a used woodworking machine on Avito.

In order to buy a universal woodworking machine and get the most out of the purchase, you must immediately choose the device that best suits your purposes.

Many people think about making such a tool and are looking for thematic videos on the network: it is quite difficult for a beginner to make a woodworking machine with his own hands on his own. Nevertheless, below you can familiarize yourself with an interesting material about a homemade woodworking machine with your own hands: a video clip can become an example for assembling your own device. More videos on this topic can be found on the net in large numbers.

Useful advice! It should be borne in mind that manufacturing a high-quality device requires experience, special equipment and an understanding of many nuances. If you doubt your capabilities, you should turn to ready-made models from manufacturers.

Which multifunctional woodworking machine to buy: device classification

Woodworking machines are divided according to priority functions. Some devices are highly targeted, while others combine the ability to perform multiple tasks. The table below will help you navigate the different types of machines.

Machine types table. Selecting a machine by purpose:

| Function | Capabilities | Machine type |

| Sawing |

|

|

| Pressing |

|

|

| Planing |

|

|

| Drilling |

|

|

| Milling |

|

|

| Sharpening |

|

|

| Grinding |

|

|

At the same time, you can choose a multifunctional machine that will combine "skills" from different categories.

Classification of machines according to the degree of versatility

There are several types of equipment, depending on the breadth of their scope.

In production, methodical processing of identical parts is often relevant, which is distinguished only by size. Special machines are suitable for this kind of work. They are tailored for a specific operation. For example, in the manufacture of cabinet furniture and doors, it is required to saw panels and boards. This is done on a panel saw, which is specialized. In order to level profiles, edges of panels, frames in furniture and carpentry workshops, edge grinding machines are used.

For a home, a universal woodworking machine, the price of which will be much lower than a specialized one, is suitable if you earn money by woodworking.Such a tool is suitable for various tasks. However, it can be too serious for a small home workshop.

Features of the universal machine:

- the advantage is the ability to replace several special ones. For example, a thicknessing-planing machine combines the functions of devices for planing and thicknessing, while taking up much less space and standing much cheaper;

- minus the universal machine - less accuracy and efficiency in comparison with special ones.

Useful advice! A universal machine is a good solution if there is little space in the workshop or workshop, and the functions of various types of machines are required to solve the tasks. It is suitable for serial and small-scale production.

If you buy a combo machine for wood for household use, it will be an economical way out for a home workshop. It can be used for various tasks: drilling, planing, sawing. At the same time, the price of a household woodworking machine is the most profitable among all types of such equipment.

Prices of woodworking machines for home, depending on the type and capacity of the equipment

Another important factor to consider when buying a machine is what maximum loads the equipment can withstand. And in this case, the determining factor is the power of the machine.

Price table for machines depending on type and capacity:

| Machine type | Scope of application and features | Power, W | price, rub. |

| Highly specialized |

|

2500-12000 | from 21000 |

| Universal |

|

450-3000 | from 16000 |

| Household |

|

1500-2000 | from 8000 |

Household machines are relevant for home use. Let's figure out which combined woodworking machine for a 220 V home is best for you.

Types of multifunctional household woodworking machines 220 V

All household machines are divided into two types:

- autonomous;

- tabletop.

Stand-alone machines and their features

Stand-alone machines are suitable for professional tasks. They take up more space and weigh more than amateur ones, but they cope with any functions from sawing across and at an angle to cutting grooves. Such a device is equipped with everything necessary for comfortable and safe operation: in its arsenal there are all kinds of stops, boxes and clamps, as well as a system for removing dust and shavings.

The power of such a unit is from 3 to 5 kW, there are usually two or three motors in the machine. Sometimes in a multifunctional device, two engines are used, operating from different power sources - electric and gasoline or diesel.

It makes sense to purchase such a machine in the case of professional woodworking.

Desktop household multifunctional woodworking machines with a thickness gauge

The bench machine is designed for amateur woodworking.In his arsenal there are 2-5 types of processing. Such a unit operates from an electric drive, the power of which ranges from 0.9 to 3 kW. This machine is ideal for a small workshop or a backyard, and its main functions are planing and sawing. You can even find or make drawings of a woodworking machine with your own hands, but without a lack of experience, you should think about buying professional equipment.

Often, for desktop household machines, the upper clamp performs the function of a planer. However, if this tool is often relevant to you, you can find a model of a household machine equipped with a thickness gauge.

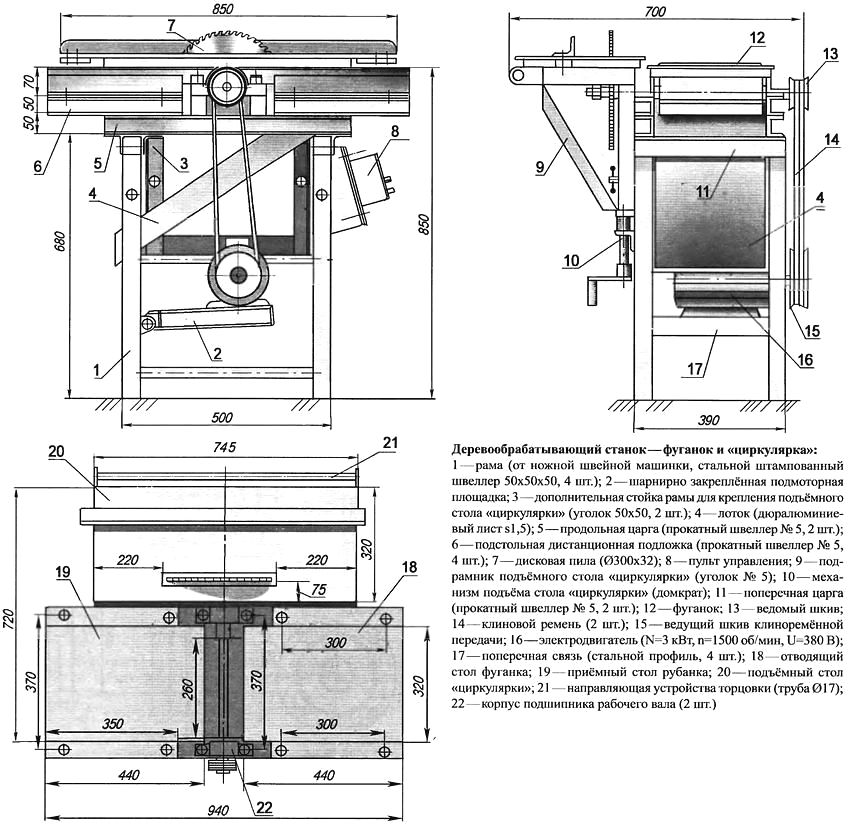

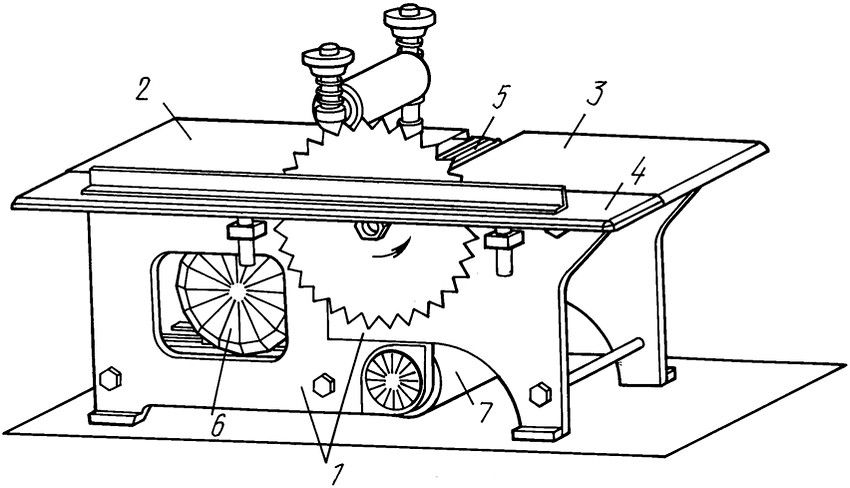

The device of the simplest universal machine with a circular saw and a thickness gauge: 1 - split bed; 2 - receiving movable table; 3 - supporting stationary table; 4 - saw table; 5 - knife drum; 6 - drive; 7 - skin drum

Multifunctional household woodworking machine: scope

You can buy a universal woodworking household machine for both semi-professional and home amateur workshop. Such devices are multifunctional and capable of performing various operations with wood.

Multifunctional woodworking machine for the home copes with the following tasks:

- sawing wood;

- planing of wood;

- milling;

- grinding;

- drilling wood, etc.

This versatility is due to the possibility of replacing the working tool. Thus, by installing a planer element, you turn the device into a planer, and if you buy knives for woodworking machines, you can saw wood beams. As a result, instead of numerous types of equipment, one machine is enough to work, which saves space, effort, time and money.

Another feature of household woodworking machines for the home is the gradual consumption of electricity, which allows you to save on utility bills.

Household machine device. Its functions and the purpose of various tools

When comparing a professional machine with a household one, it becomes clear that a household universal device is compact. This is facilitated by the presence of this engine: the electric motor is hidden under the working table in the bed, and thanks to the zoning of the tabletop surface, it is convenient and safe to work. Usually there is a plane on one side of the table top guide bar and a circular saw on the other. On the side, on a small area, you can place parts, and fix cutters and drills on the chuck. The set for the machine includes rulers, clamps and stops.

Useful advice! There are machine models on which you can simultaneously perform various types of work. However, keep in mind that the quality of processing with a universal machine will be lower than with a special one.

The household machine is suitable for amateur woodworking in a home workshop, as well as small carpentry, furniture production. When choosing a machine, be sure to take into account the area of the room and place the unit so that you always have convenient access to the working unit.

The working tool receives energy from the engine. When buying a household woodworking machine, remember that the performance of the device is directly proportional to the drive power and the rotor speed.

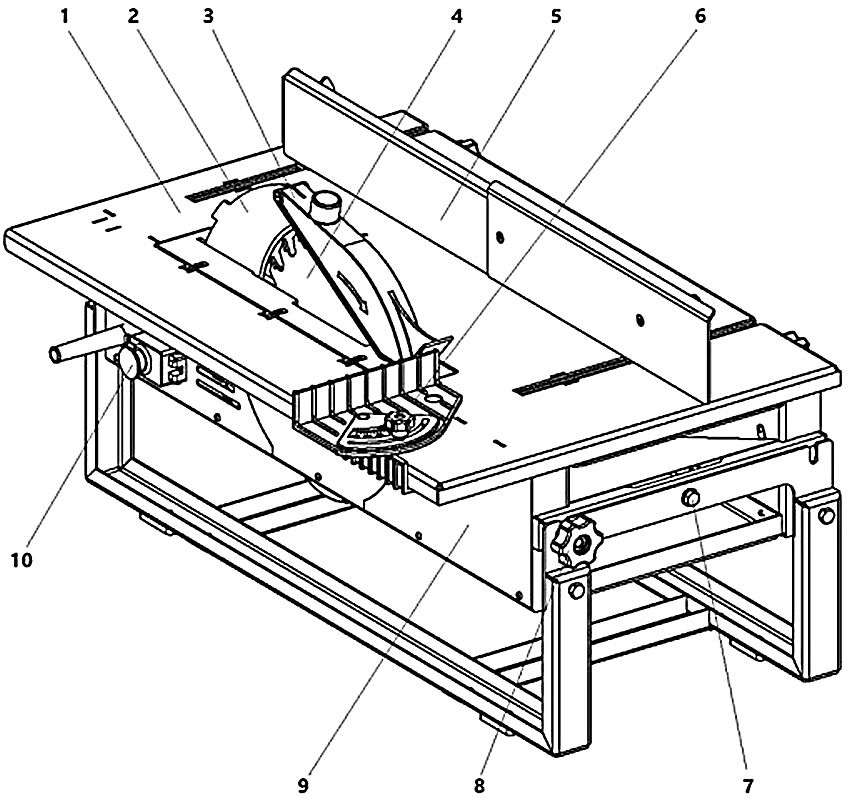

General view of the machine in the sawing mode: 1 - saw table; 2 - riving knife; 3 - protective casing; 4 - saw blade; 5 - guide ruler; 6 - device for cross-cutting at an angle; 7 - axis; 8 - handles; 9 - drive mechanism; 10 - switch

Basic working tools of universal woodworking machines for the home

The function of the machine depends on the "attachment" that is currently selected as the working tool. This could be:

- drill;

- planer shaft;

- cutter;

- circular saw;

- abrasive wheel;

- thicknesser shaft, etc.

What functions are performed by various tools:

| Function | Tools |

| Sawing | circular saw, on some models - knife module |

| Planing, planing | the knife shaft must be installed in the center of the surface allocated for this task, as a rule, on the largest section of the tabletop |

| Milling, drilling | often (for reasons of space saving) these functions are combined into one; the knife shaft is located in a horizontal plane, and the tool is fixed with a universal chuck |

| Grinding | the grinding wheel can be installed in the drilling module, in some models special rollers are provided for the belt |

In addition, the machine may have additional functions. Such as:

- magnetic switch;

- vibration suppressor;

- smooth start;

- maintaining engine speed at the same level at any load;

- prevention of overheating with a thermal relay;

- auto feeding of parts;

- emergency shutdown function;

- protection against power surges.

Desktop Mini Woodworking Machine for Home

Often when working on a universal woodworking machine with a thickness gauge or other tool, it is important to adjust the depth of cutting, milling or sawing. In this case, you can change the height of the desktop. To increase the depth, the table is lowered, and if the depth needs to be reduced, it is raised.

A competent choice of woodworking equipment, studying the possibilities and nuances of the operation of various machines will allow you to get the most out of the purchase and choose the device that is suitable for your needs

Helpful advice! For small industries dealing with medium-sized parts, a machine with a welded bed is suitable. If we are talking about large products, equipment with a cast bed is needed, the cost of which is much higher.

When choosing a machine, be sure to pay attention to the rigidity of the table. It is especially important not to forget about this if you decide to make a woodworking device yourself. The more durable the table is, the less vibration the objects that are on it are, which ensures greater precision in processing the workpiece. The best option in terms of rigidity is a cast work table.

Choosing a household machine: important characteristics

How to choose the most suitable machine. Criterias of choice:

| Machine characteristics | Selection features |

| Power supply | household machines are connected to a two-phase 220 V network, industrial machines are powered from a three-phase 380 V |

| Electric motor power | the minimum power of the desktop machine is 1500 W, which allows the device to cope with small loads; for intensive work, a machine with a power of 2200 W is required |

| Rotation frequency | the number of revolutions that the tool makes per minute (determines the processing speed and its quality); the minimum speed is 2800 rpm. per min., the maximum indicator exceeds 7500, for work at an amateur level, 3600 rpm is enough. in min. |

| Saw blade diameter | affects the cutting depth of the tree (it is worth choosing the largest value available), the maximum possible diameter of the circular saw is 260 mm |

| Planing depth | the value can be from 0 to 3 mm per set |

| Bevel cutting function | the angle can be from 0 to 45 °, however, in the home workshop this function is rarely in demand, so you can save on it |

| Workpiece dimensions | may differ depending on the type of processing, so please pay attention to this figure when buying |

| Bed material | amateur models are made in welded steel cases, professional ones are made of cast iron - they are heavier and more stable, which ensures greater accuracy in performing tasks, but they also cost more |

| Weight and dimensions | here one should proceed from the area of the workshop and the free space in it |

Helpful advice! The more versatile the machine is, the higher the cost, so it makes sense to focus on the tasks you really need. But saving and buying a used device can be risky - it is impossible to guarantee the quality of such a machine.

Advantages of the combined universal woodworking machines D300, D400 and other models

Like any other equipment, multifunctional woodworking machines are not devoid of both advantages and disadvantages. Below we will try to figure out what are the advantages of purchasing such a machine and consider the possible disadvantages.

Machine advantages:

- multifunctionality - you can carry out several operations on one device. For example, to get a finished product from lumber, you must first dissolve the trunks on the sawmill, then thickness the boards or process them with a milling cutter or jointer. All this can be done within the workshop on one device, saving time, effort and money;

- benefit - it is easier and cheaper to buy one device than several specialized ones;

- ease of use;

- expediency and practicality - a number of functions are required so rarely that it makes no sense to buy a separate special device. Woodworking machines Ant and devices from other companies include these functions, among others, without requiring spending on a separate unit;

- quiet work, which is especially important for a home workshop;

- compactness - most of the tools are housed in a stand-alone or desktop case that fits easily on a writing, kitchen table or workbench.

Disadvantages of household machines:

- such a machine cannot be altered, improved to fit your needs;

- due to the combination of many functions, some tools may suffer and not perform their work in the desired quality;

- a household desktop machine is not suitable for serious production - it is more expedient to buy specialized machines and hire the appropriate specialists.

Helpful advice! Before buying, think about the functionality of the machine you need. Analyze the model you like: it may be easy to replace the missing features with the help of hand tools. This option is especially convenient if you do not plan to use the missing functions too often.

Woodworking machines allow you to create unique objects from wood without spending a lot of effort and time

Comparison of different models of woodworking machines

Both domestic and foreign manufacturers of woodworking machines are represented on the modern market. Among Russian manufacturers, the firms Corvette and Muravei have proven themselves best. In the foreign market, Jet, Maksita and Hitachi are distinguished by their reliability.

To make an informed choice, it is worth comparing the characteristics of various machine models and finding the most suitable option for your tasks. We compared the models BELMASH UNIVERSAL-2000, STAVR SDM-3/2000, CRATON WM-Multi-08, ENKOR Corvette-320, as well as leading models of household multifunctional woodworking machines Ant.

Comparison of indicators of machines of different models:

| Machine model | BELMASH UNIVERSAL-2000 | STAVR SDM-3/2000 | CRATON WM-Multi-08 | ENKOR Corvette-320 |

| power, kWt | 2 | 2 | 1,6 | 1,5 |

| Rotation frequency, about in min. | 6000 | 3800 | 8000 | 3500 |

| Cutting depth, mm | 97 | 85 | 75 | 70 |

| Platform size, mm | 700x474 | 530x150 | 746x210 | 964x210 |

| Weight, kg | 39 | 61 | 35 | 123 |

| price, rub. | 20600 | 30940 | 31429 | 39610 |

It is worth noting that the functionality and reliability of parts of domestic models is not inferior to foreign ones, while they are much cheaper. The only complaints can be about the build quality, since most of the models are assembled in China.

Helpful advice! You can save a lot by purchasing a domestic machine and using video instructions to assemble it yourself. This way you get an excellent quality machine at no extra cost.

Comparison of indicators of various models of machine tools Ant:

| Machine model | SD-3-00 | SD-3-02 | SD-3-03 | SD-4-00 | SD-4-01 | SD-5 | SD-6 |

| Power consumption, kW | 2 | 2 | 2,7 | 2 | 2,7 | 2 | 2 |

| Rotation frequency, about in min. | 4200 | 4200 | 4200 | 4200 | 4200 | 4200 | 4200 |

| Cutting depth, mm | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Dimensions, cm | 3x65x100 | 73x56x58 | 73x66x58 | 73x56x38.5 | 60x66x38.5 | 60x50x45 | 60x50x66 |

| Weight, kg | 75 | 70 | 75 | 50 | 60 | 40 | 50 |

| price, rub. | 46130 | 46130 | 49350 | 36340 | 39570 | 26770 | 31720 |

Important rules for working on a universal machine

As with any other piece of equipment, certain rules must be followed when using a universal woodworking machine. This will ensure high quality of work, efficiency, and also provide an adequate level of safety. So:

- before starting work, sort the lumber by quality and size;

- when making planing, first completely process one surface, and then the second. It happens that after the first pass, defects of the wooden workpiece become noticeable and there is no point in processing it further;

- choose a well-dried tree for work. Thanks to this, the load on the equipment will be less, and the quality of work will be higher;

- in order to prevent downtime in the event of a breakdown, try to always have one type of cutting tool in stock;

- do not sharpen knives for woodworking machines yourself. Professionals have special sharpeners - with such processing, the tools will serve you much more efficiently and longer;

- for cutting wood, choose a disc with sparse coarse teeth, and for a clean cut - a disc with frequent fine teeth;

- for ease of use, attach the machine to a workbench. Use the fasteners provided by the manufacturer for this.

Multifunctional woodworking machines: video reviews of devices