While supporting the general theoretical rejection of the use of objects made of synthetic materials, one cannot but admit that certain chemical compounds are simply irreplaceable in our daily life. These include a transparent epoxy potting resin. Admiring the external naturalness of artificial amber or the radiant purity of the "stone" countertop, we don't even think about the origin of the material.

Epoxy resin is one of the best materials for making floors, beautiful glossy finishes, countertops, decorations

Content

- 1 What is epoxy resin, material characteristics

- 2 The main ways of using transparent epoxy

- 3 Initial characteristics of transparent epoxy resin

- 4 Features of the process of preparing epoxy for pouring

- 5 How to make epoxy at home

- 6 Hardeners for epoxy resin: functions, types, application features

- 7 Is it possible to make a DIY epoxy hardener

- 8 Epoxy resin products: bijouterie, furniture, decor

- 9 DIY original epoxy products

- 10 How to use epoxy: safety rules

What is epoxy resin, material characteristics

Resin is a substance that hardens under certain conditions. Distinguish between natural (wood) and synthetic resins. Epoxy (abbreviated from "epoxy resin") is a polymer resin, that is, a chemical composition of oligomers - molecules with a small limited mass.

Transparent epoxy resin has a two-component composition

The main characteristics of this substance:

- resistance to moisture, ultraviolet light;

- not affected by acids, alkalis, halogens;

- soluble in acetone and esters;

- does not emit harmful volatile substances.

The transparent epoxy resin is two-component. The final product is obtained during the implementation of two chemical processes. In the first stage, a low molecular weight linear thermoplastic mass is created. On the second, which is curing, a solid, insoluble and infusible substance is formed by obtaining a spatial structure in it.

The ability to quickly convert from a liquid to a solid is a very valuable property of epoxy. In addition, it can firmly bond surfaces. The combination of the above characteristics makes this composition in demand.

Basic applications transparent epoxy

The scope of application of epoxy resin is quite wide.The substance is actively used both at home and at work. Constantly improving technological processes, obtaining more and more new formulations with improved qualities increase the possibilities of application.

Traditionally, pouring resin is used in various industries for the following purposes:

- for impregnating fiberglass, bonding parts. Scope of use: construction, aircraft and mechanical engineering, radio electronics, electrical engineering, fiberglass production, repair of ships and cars;

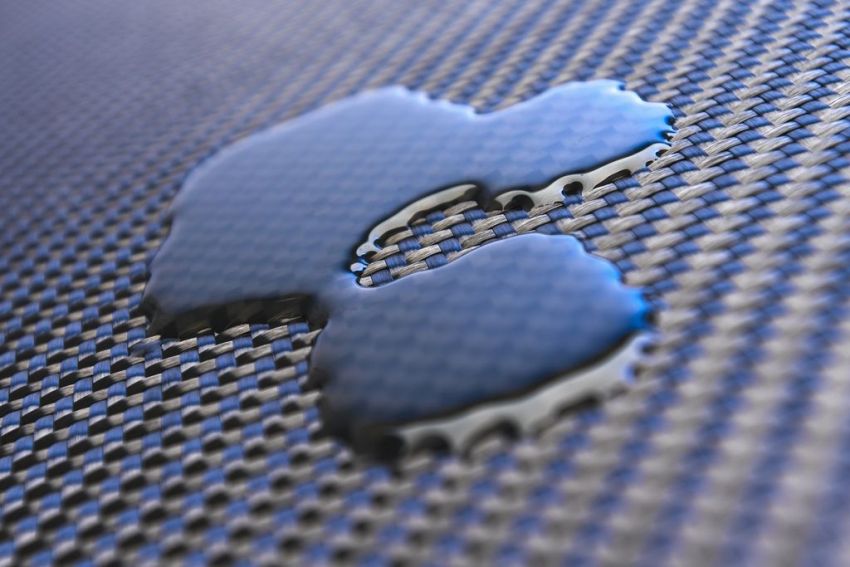

- to create a waterproofing layer. The material is used for covering the walls of buildings with high humidity, basements, swimming pools and other tanks for liquids;

- if it is necessary to create chemically resistant coatings for external and internal surfaces, as well as for applying a protective layer to porous materials;

- for pouring into molds in order to obtain transparent parts and objects that can subsequently be cut, sanded, that is, subjected to mechanical processing.

Useful advice! If you need to glue hard surfaces, it is better to purchase a special epoxy glue, and not use any resin composition. The connection effect will be in any case, but a special material will allow the process to be carried out more efficiently and efficiently.

Epoxy for decorative work is characterized by fast curing, which is based on a chemical polymerization reaction

Initial characteristics of transparent epoxy resin

Almost all types of epoxy are transparent in their original state. Some may have a yellowish tint. After connection with the hardener, the yellowness does not disappear. This must be taken into account if it is necessary to have a transparent epoxy layer.

Some high viscosity polymers form bubbles after hardening, which significantly reduces the transparency effect. You can get rid of them by heating, which should be performed before pouring or after it, in the latter case, burners or other heating systems are used. This process is quite troublesome and does not always give an ideal result.

Finished epoxy resin crafts can lose transparency over time when exposed to ultraviolet light and oxygen in the air. Such troubles can only be avoided by using resins containing UV protectors and antioxidants.

Therefore, when choosing an epoxy resin in order to obtain a solid transparent material, the following must be considered:

- resin shade before adding additives;

- viscosity grade;

- chemical composition.

Transparent epoxy resins can be used for making small parts (jewelry, souvenirs, decor), and for larger fillings (countertops, shelves, etc.). The technology for using epoxy resin may vary depending on the characteristics of the products.

Useful advice! To be sure (especially when performing large fillings) that the composition of the resin is suitable for the intended purposes, it is better to purchase a probe - a container with a small amount.

Features of the process of preparing epoxy for pouring

The preparation of the epoxy resin composition should be carried out in accordance with the instructions, which in one form or another are attached to each container. The lack of a description of the sequence of actions indicates the dubious qualities of the product, which probably also does not have certification.

When mixing the epoxy components, proportion is of the utmost importance. The standard ratio of resin to hardener is 10: 1. In special formulations, the proportion can vary from 5: 1 to 20: 1.The preparation methods for small and large volumes also differ. For small quantities, only stirring is sufficient. The large mass must be preheated to reduce the viscosity. It should be borne in mind that an increase in temperature by 10 ° С accelerates polymerization at least twice.

Heating the resin, it is required to control the temperature. If the substance boils, it will begin to foam, cloudy. Such a composition is unsuitable for use. You can use thinners to reduce the viscosity. It should be borne in mind that even 5–7% of such additives in the composition significantly reduce the quality of the material.

The problem of how to clean, that is, how to dissolve the epoxy resin, remains relevant. It is better not to allow the spots to completely solidify. If this does happen, the most effective method is mechanical, but it is not applicable to all surfaces. The use of a special solvent for resins also does not preserve the surface. Heating or freezing can be used if conditions permit.

None of the methods provide a guarantee of complete cleansing.

How to make epoxy at home

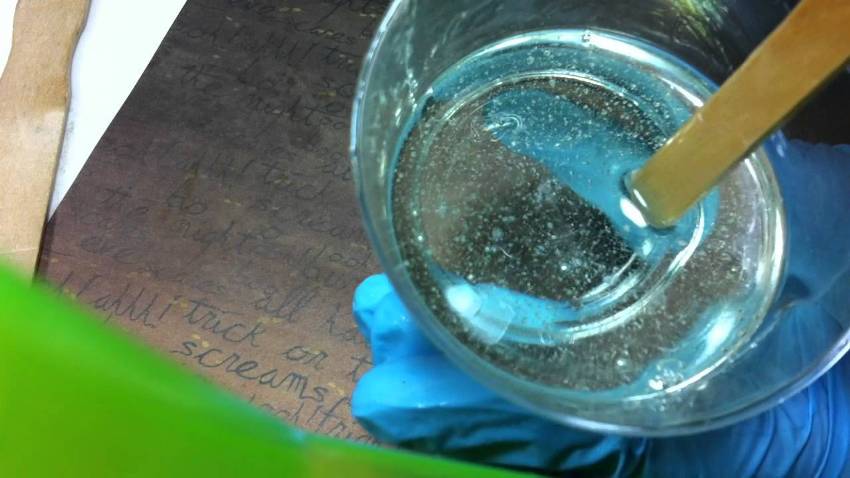

It is not difficult to prepare epoxy at home. To do this, you need to prepare the necessary container, a measuring container and a stick (or other similar object) for stirring. The process of making epoxy resin with your own hands includes several stages:

- Choice of premises. It should be ventilated, have a temperature of about 25 ° C and a low level of humidity.

- Performing a test connection. Mix a small amount of epoxy. If the characteristics (degree of transparency, viscosity, curing time) suit you, you can go to the full volume.

- Using a cold mixing method. Add 1 part hardener to 10 parts of resin. Stir with the same intensity and in one direction - in this case, the mass will be more uniform.

Useful advice! At home, it is better not to cook large volumes (more than 5 kg). When mixed, a lot of heat energy is released, which will accelerate polymerization and quickly render the composition unusable.

The process of making epoxy resin with your own hands is not as complicated as it seems at first glance.

To understand how to make the epoxy plastic enough, you should also perform a test connection, taking into account all the fillers planned for use.

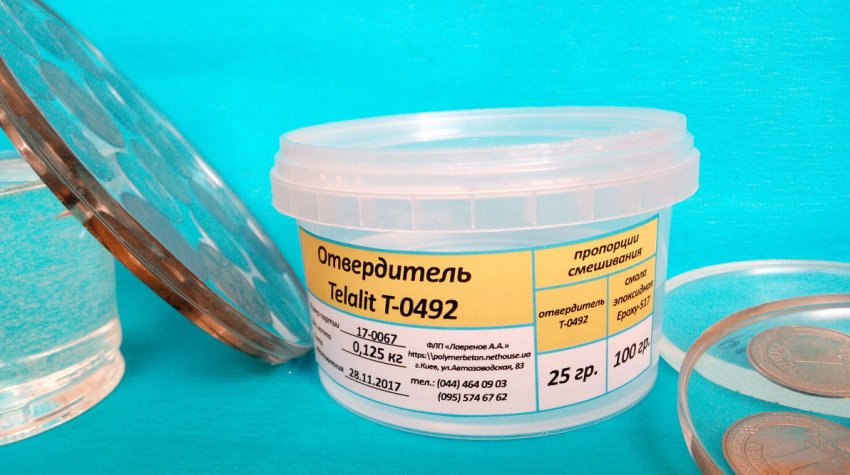

Epoxy resin hardeners: functions, types, application features

The importance of the correct application of hardeners for epoxy mixtures has already been discussed above. To understand how to dilute epoxy with a hardener, you need to know the qualities and distinctive properties of the latter. It is by the characteristics of the additive that the characteristics of the composition as a whole are determined.

Epoxy hardeners are chemically divided into two types.

Amine. They include amines, diamines, polyamines. These are the most common hardeners and are most commonly used in the home due to their ease of use. They do not require the creation of certain temperature conditions, the process takes place even at room rates. This method of curing is called cold.

Acid hardeners. Created on the basis of acids and their anhydrides (maleic, phthalic, hexahydrophthalic and others). It should be noted that the quality of the hardened layer in the presence of acid additives is much higher. However, the application process is much more complicated, since heating (100-200 ° C) of the mass is required to improve its physical and chemical properties. This method of curing is called hot.

The price of epoxy resin (complete with filler) largely depends on the type of hardener.

Useful advice! Given the importance of the hardener for the quality of the final result, you should not save on price and purchase cheap types. It is better to buy the options recommended by the manufacturer for a particular type of epoxy.

Is it possible to make a DIY epoxy hardener

The use of epoxy requires precise adherence to certain technologies. Therefore, it is better to use ready-made formulations. Situations where epoxy remains and the hardener is used up are quite common. Is there an alternative, that is, is it possible to make this component yourself? It is possible, but only on condition that the necessary chemical components are acquired and combined in the required amount.

Etal-45M, CHS-Hardener P-11, Telalit 410, diethylenetriamine can be found on the market. The quality of the hardener obtained in the course of home production should definitely be assessed by test, that is, by mixing it with resin in a small amount. To understand how to dilute epoxy and a test hardener, you can use the following tips and a procedure:

- Prepare a small container and two measuring cups or syringes. When using syringes, it is easier to control the quantitative indicators of liquids.

- Collect a certain amount of resin in one syringe, pour into a container. Then draw the hardener into another syringe and in a ratio of 10: 1 introduce it into the resin.

- Place the composition intensively, but without the use of electrical mechanisms, leave to harden on the surface (or similar) intended for use.

- Observe the polymerization process. If you need to make adjustments, you should refer to the same method, but using different proportions.

Related article:

Polyurethane stucco molding in interior design: secrets of original design

Types of polyurethane moldings. The relevance of the use of stucco decoration in different interiors. Installation secrets.

Dry alcohol can be used as a home hardener. It should be crushed and combined with resin in a 10: 1 ratio. This method should also be tested on small volumes.

Important! It is necessary to combine substances in exactly the same sequence as indicated above. Otherwise, the polymerization process may be accelerated and will not give objective results.

Plasticizer as filler for epoxy

Along with the hardener, the necessary component of the epoxy resin is a plasticizer. Products made with such a filler do not crack or break. It is imperative to add a plasticizer when using large volumes of epoxy, that is, to create thick layers, since cracks can form even during the hardening process.

One of the plasticizers for epoxy resin is dibutyl phthalate, abbreviated as DBP. The substance is rather difficult to mix with the resin, so the level of plasticity is low. The additive is quite enough to protect products from cracking during hardening, from low temperatures. To enhance the effect, mixing the resin and this plasticizer is carried out in a water bath.

The plasticizer Laproxide DEG-1 is recognized as more effective. It is an epoxy by itself, mixes well, an addition of 5–7% gives excellent results. The composition with DEG-1 (without hardener) can be stored for as long as necessary.

S-7106 thinner is actively used for plasticization of epoxy resins. When adding it, it is necessary to use the hardener in the usual proportion to the total amount of the composition.That is, 110 g of hardener should be added to 10 kg of epoxy and 100 g of this thinner.

Epoxy adhesives can be tough and malleable. Hard ones contain resin and hardener. Plastic ones are available with additives that slow down the hardening process, but provide stronger adhesion. It is impossible to answer unequivocally how much epoxy glue with such a filler dries. Time largely depends on temperature conditions. If there were no violations of the technological process, then the maximum value is 24 hours.

Epoxy resin products: bijouterie, furniture, decor

Transparent epoxy resin is a multifunctional product. Using it, you can make finished products, decorate models from another material, connect separate parts into a single whole. The effect of artistic processing is present in any element where such a polymer is used. Transparency gives a similarity to glass. It is this property that contributes to the widespread use of epoxy when creating souvenirs.

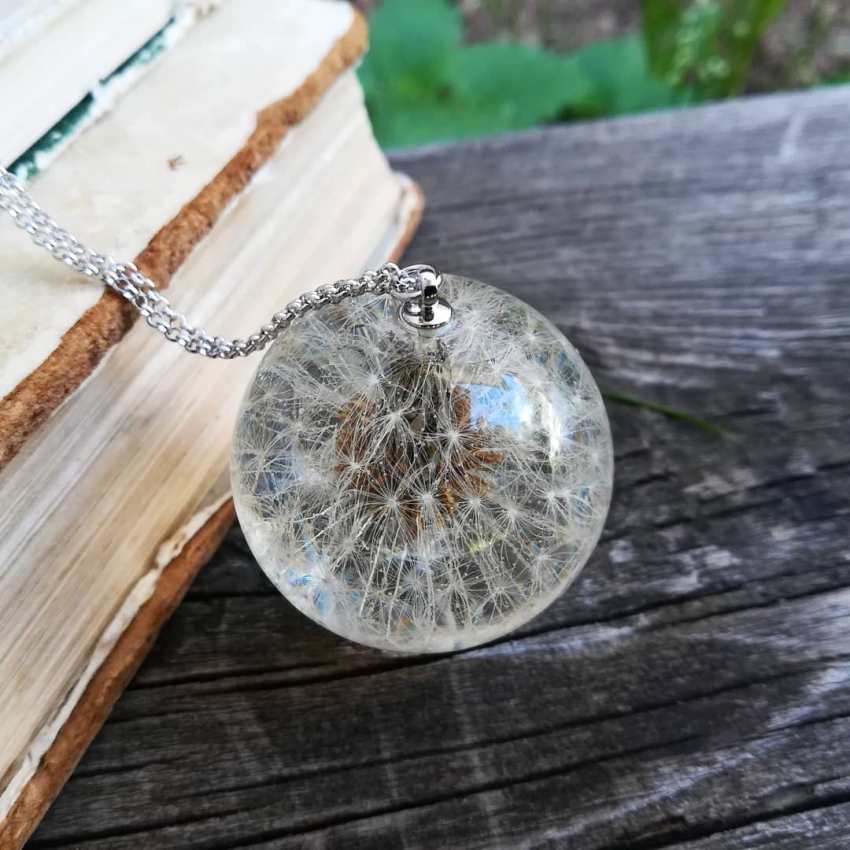

Flooded natural materials: leaves, flowers, cones, grains, etc. - become interesting crafts. Epoxy resin lends itself to tinting, and this allows the material to be used for the manufacture of various jewelry. Exclusive pendants, earrings, clips, brooches, hairpins and other accessories are very popular with modern women of fashion. The properties of the material make it possible to create imitations of precious stones that only specialists can distinguish from natural ones.

Modern design developments - furniture made of epoxy resin. Original and durable countertops, shelves, decorative elements of backs, legs can be found in interiors of premises of various styles. Recently, clear epoxy has been used to create a 3D effect floor.

Variety of epoxy and wood products

Epoxy resin and wood are an excellent combination from both an aesthetic and practical point of view. The polymer composition fills the pores of the wood, provides a secure connection and forms a durable coating or insert. The price of epoxy is high, but if you take into account the quality of handmade jewelry or exclusive furniture options, then the use of this chemical composition is quite justified.

Epoxy can fill in wooden molds or create a top coat. The first method is often used in jewelry making. Hollow rings, hearts, stars, leaves, etc. are filled with a colored or transparent composition, resembling amber, emerald, ruby, or simply creating volume.

The second method is used in the manufacture of furniture. A layer of epoxy is applied to the base, resulting in an original countertop. Various object inserts can be used as decor.

Shelves, flower stands, vases are made of wood and epoxy resin. Products can be illuminated with luminescent or fluorescent additives introduced directly into the epoxy composition, or using an LED strip.

Useful advice! When making products from transparent epoxy resin and wood, it is necessary to avoid the contact of wood processing waste on the polymer layer. This can significantly reduce the transparency effect.

DIY original epoxy products

Epoxy resin allows you to realize creative ideas without spending a lot of time and effort on it. As mentioned above, the transparent composition is easy to prepare yourself. Then you can create an exclusive piece of jewelry - a wrist bracelet. For this you will need:

- transparent polymer composition;

- molds for epoxy resin - molds;

- decor (dried flowers, coins, artificial or natural stones, etc.).

It is necessary to lay out the decor in the form, fill it with the mixture, use a toothpick to fix the object inserts, remove the bubbles (if they appear), and allow to harden. The finished product should be sanded (you can use a nail cutter) and varnished.

It is not difficult to make an unusual backlit shelf from epoxy resin. To do this, you will need a piece of unedged board, a sanding tool, resin, hardener, fluorescent powder. Shelf manufacturing steps:

- Sand the board, remove bark and loose knots. The more defects the wood has, the more original the product will be.

- Dilute the resin by introducing all fillers, fill in cracks and depressions over the entire surface, and allow to harden. If there are defects along the edge of the workpiece, a restrictive flange will be required, which must first be made of thin metal or wood board.

- Sand the product and hang it on the wall.

It is worth calculating how much epoxy, fillers and a piece of unedged board cost. It turns out the amount corresponding to the most inexpensive chipboard shelf, but in terms of decorativeness, the products are incomparable.

Compositions based on transparent epoxy are used for making jewelry, key rings, pendants, bijouterie

Transparent epoxy potting resin: tips for novice modelers

Mastery comes with experience. In the case of using epoxy, this is especially true, since there is a lot to try and check. A few tips will be useful for beginners to help them quickly master such an at first glance, but rather capricious material:

- The price of transparent epoxy is high - from 800 to 10,000 rubles per kilogram, which depends on the purpose and chemical composition. So that the costs are not in vain, it is worth starting any work with testing.

- When using molds for pouring, you need to lubricate them with technical vaseline for quick extraction of finished products.

- It is required to cover the work surface, where the pouring will be carried out, with oilcloth or thin wood board. The paper will not provide the protection you need.

- In case of the formation of flakes or balls in the epoxy resin, the liquid should be heated, but not more than to 60 ° C.

- If bubbles appear in the solidified layer, you can easily remove them by inserting a straw and blowing through it.

- It is worth taking a balanced approach to the low cost of epoxy. Products made from this material can quickly turn yellow. Look for the label "UV filter" on the packaging or container.

- Before using transparent epoxy, it will be useful to put it to a closed heat source, for example, to a battery - the composition will harden faster.

When buying epoxy resin and hardener, you should check with a specialist for what purpose it is intended

Useful advice! When buying clear epoxy, you should pay attention to the expiration date. The standard indicator is 12 months. If it is smaller, the composition is likely to have poor quality characteristics.

How to use epoxy: safety regulations

Epoxy resin, like many other chemical compounds, requires careful handling and adherence to certain rules. They mainly relate to the composition in a liquid state. Some epoxy components can cause burns, dermatitis, poisoning, and affect the upper respiratory tract. Knowing how to work with epoxy can help prevent damage and injury. Basic safety requirements:

- Do not combine components in utensils intended for cooking.

- Wear protective clothing, including gloves, before working with epoxy. A protective cream should be applied to your hands first.

- When machining cured material, wear glasses and a respirator.

- If the epoxy does get on the skin, you must immediately wash it off with warm water and soap, or wipe it off with a swab dipped in denatured alcohol.

- Work with epoxy resin can be carried out only in those rooms where supply and exhaust ventilation is organized.

Despite the saturation of the market, more and more new epoxy compounds appear. This material is a serious competitor to wood, glass, metal, ceramics. Products made from it are durable, reliable, do not lose aesthetics for a long time. In addition to its high practicality, transparent epoxy resin makes it possible to create interesting interior items. Provided the correct technology is used, epoxy is a versatile material for work and creativity.